Progress

Improving the profitability of copper ore processing

Summary: Considerable savings potential in the energy sector, grinding media consumption as well as easy installation and maintenance are steadily shifting the focus onto the latest developments in Vertimill technology. Thanks to the field-proven advantages of this technology, an increasing number of copper processing plants are expected to introduce this technology to cover the biggest share of their milling needs – essentially to further improve overall profitability.

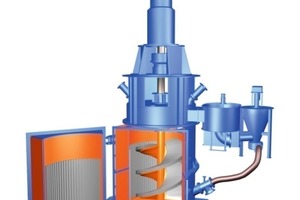

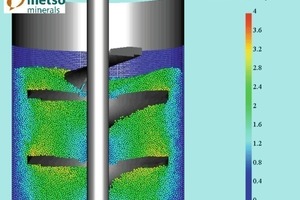

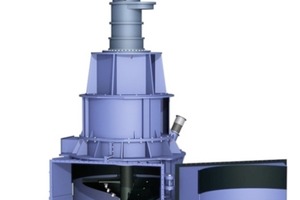

1 Increasing grinding efficiency with the improved Vertimill

Having acquired the licence in 1979, Metso (then Koppers) has exclusively supplied the Vertimill and steadily further developed it. Originally developed in the 1950s for mineral applications in Japan, the technology did not initially meet the high requirements for metal mining – although Metso focused on this sector from the start, the mill was not regarded as sufficiently rugged. For this reason Metso redesigned the mill, improved its grinding efficiency, minimized maintenance times, and at the same time maximized its lifetime. In...