Thermo-mechanical treatment

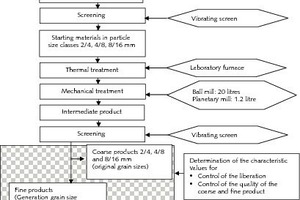

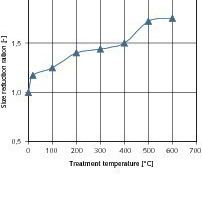

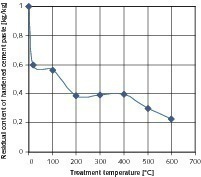

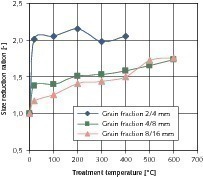

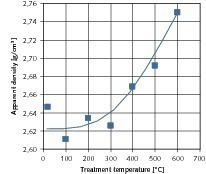

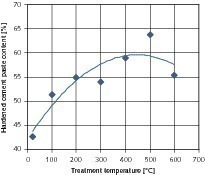

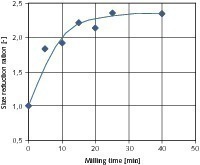

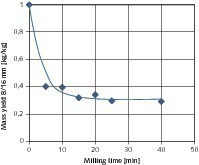

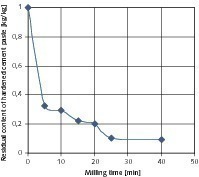

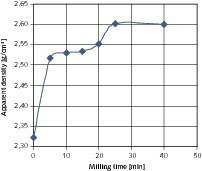

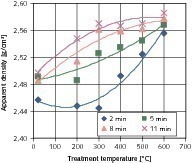

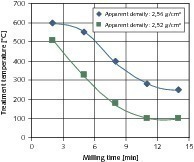

Study of the factors influencing thermo-mechanical treatment for recycling used concreteSummary: The liberation process developed is intended to improve the quality of concrete recyclates for the production of fresh concrete. For this end, thermal and mechanical treatment is combined. It was empirically proven that even moderate temperatures of around 300°C are sufficient to make the hardened cement paste (HCP) brittle, so it can then be removed by means of mechanical treatment. The products of this process are aggregates with properties close to those of natural aggregates as well as a fine-grained material high in hardened cement paste that can be further processed to a binder.

1 Introduction

Concrete is the most commonly used building material in our time. Around 8000 mill. t concrete are produced annually worldwide [1], including around 250 mill. t in Germany [2] and around 3000 mill. t in China [1]. At the same time, large volumes of concrete rubble are produced. The forecast for Germany, which is based on the concrete volumes produced and assumptions regarding the lifetime of concrete structures, indicates that around. 100 mill. t of concrete rubble could be produced by the year 2020 [3]. The volumes of concrete rubble expected in China range between 200 and...