Safety first in mining

Renaissance of heap leaching for valuable metals

Summary

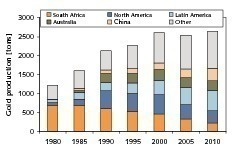

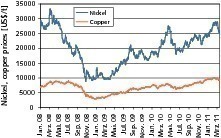

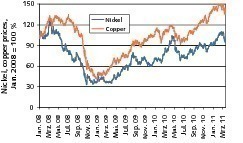

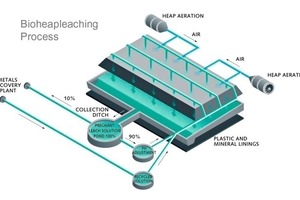

A very broad range of processes are used for the recovery of valuable metals. Heap leaching as a hydrometallurgical process is one of the cheapest methods and particularly useful in the case of ores with a low metal content. These characteristics are especially attractive to so-called junior mine operators who have relatively little available capital. However, the subject of leaching is a controversial one, because its use for the recovery of gold and silver requires the use of highly-toxic sodium cyanide as the leaching agent and therefore involves a number of hazards. On the other hand, the biological heap leach processes that have become established for nickel and copper recovery have proved to be environmentally-sound methods. This report provides details of market trends, technologies and safety standards and discusses the economic background of selected projects.

1 Introduction

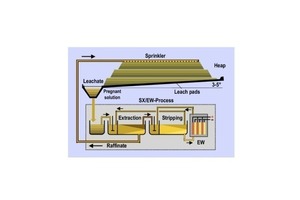

Heap leaching is the term used for hydrometallurgical extraction processes in which crushed and ground ore is heaped up and then sprayed with an aqueous chemical solution in order to dissolve the valuable metals out of the rock [1]. Since the 1970s, heap leaching has become accepted as a practical and cost-effective process for recovering valuable metals like gold, silver and copper from ores with a low metal content. More recently, the process was also used for recovering nickel, zinc and other metals. Relatively low capital cost and operating expenses compared to conventional...