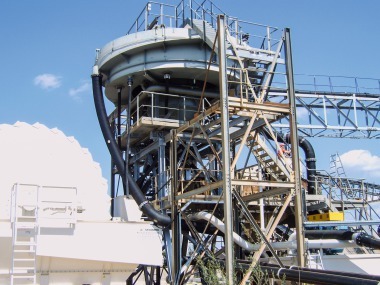

SWO supplies integrated handling technology for gravel works in Babenhausen

The SWO-Schiffswerft Oberelbe GmbH, based in Bad Schandau near Dresden, has supplied the complete conveying and handling equipment for a new extraction area in Babenhausen (Fig. 1). Originally an extension of the quarry pond was planned; this was not possible for nature conservation reasons. It was necessary to bypass a forest area. The existing floating belts on the exhausted pond were extended to cross the pond.

This consists of a catamaran with transverse pontoons and a centre distance of 191 m, a land-to-water belt with a centre distance of 35 m as well as 3 x 200 m catamarans from the exhausted pond, The following section is an overland belt with a centre distance of 425 m (Fig. 2), which can be extended to 825 m. The drive power was geared to match the maximum centre distance of 825 m.

In the new extraction area a separate pond was formed with a BEYER floating dredger of the type KAK 360, a 5-fold SSV floating chain with a centre distance of 25 m (Fig. 3), and a catamaran with a centre distance of 100 m, which can be lengthened to 200 m. Here too the drive power was geared to the maximum centre distance. And finally there is a water-to-land belt with a centre distance of 30 m. The handling rate of the entire plant is 450 t/h, the total conveying length of the plant measures around 1500 m.

www.beyer-viernheim.de