New developments in Outotec Grinding Service products

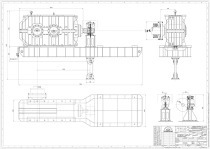

Outotec has developed the Outotec hydraulic Inching Drive system to improve equipment safety and maintenance productivity and the Outotec Barricade for superior sealing performance. The hydraulic Inching Drive system is an auxiliary drive that has been developed to ensure safe and efficient mill installation and maintenance. The drive is capable of rotating the mill in either direction during maintenance operations. The drive system consists of a planetary gearbox powered by a hydraulic drive motor. The joystick control allows for variable speed mill rotation, enabling precise mill positioning during installation and maintenance. The captive key interlock prevents operator bypass and ensures safety of personnel and equipment.

The new Outotec Barricade seal arrangement solves the issues around the effective sealing of grinding mill main bearings. The Barricade seal replaces and improves the older seal arrangements with its design incorporating uniform lip tension, enhanced seal stability and provides superior sealing performance. The Barricade arrangement is now standard supply for all new Outotec mill installations. Additionally, the Barricade can be easily retrofitted to many existing mills.