Pneumatic conveying of abrasive material

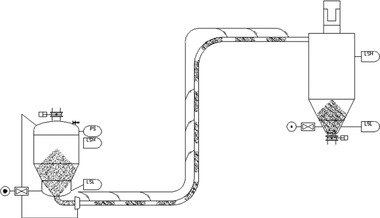

Gericke delivers under the brand name pneuwork® dense phase conveying technology for abrasive or high temperature products. The construction of the pressure vessel and of its accessories is specially designed to ensure a reliable and durable operation in heavy duty industries. The vessel is equipped with a fluidising bottom, a special wear resistant conical inlet valve. Combined with the diverter valves and anti-abrasion deviation pot, the Gericke Pneuwork conveying technology incorporates all necessary parts for a robust and efficient material transfer. Gericke pneuwork® systems (Fig.) are...