A classic experiences a technological leap - the MSizer extend

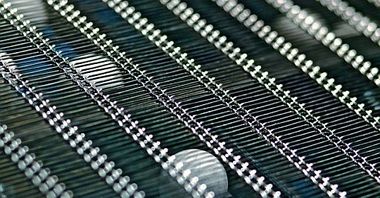

Virtually every single industry out there uses the popular Sizer to screen their bulk materials today, and yet, the basic working principle behind the machine has remained essentially unchanged ever since Dr. Fredrik Mogensen patented it in the 1960s: Screen decks are arranged on top of each other and are inclined at a pre-calculated angle as the mesh sizes become progressively finer towards the bottom. Meanwhile, vibration motors or exciters are used to make the frame holding the screen linings vibrate. As a result, the finer particles in the material being screened flow very quickly, almost vertically, through the coarser meshes in the upper deck, while coarser particles are separated out from the flowing material.

The screen linings’ varying inclinations ensure that the openings function as a smaller mesh size, making it possible, in comparison to flat screens, to use relatively large mesh sizes while maintaining a high level of grading quality. Designing the screen lining mesh sizes to be relatively large in relation to the particles being graded and that different particle sizes are separated from the material flow is crucial in effectively preventing blinding and ensuring long screen lining service life. Above all, however, the working principle behind Sizer machines enables operators to benefit from high throughput levels while minimizing the equipment footprint.

An optimized heart for the most stringent standards

With its new MSizer extend, which will be making its debut at Powtech 2017, Allgaier-Group will be presenting a fully re-engineered version of its screening technology powerhouse. It all started with the company’s design engineers taking a close look at the heart of the Sizer: the screen box. The result of their work? An optimized geometry for the screen deck layout that has improved not only the system’s grading quality and capacity, but also its overall height.

Depending on the specific application involved, the MSizer extend features two to six screens arranged on top of each other, with the topmost screen having the smallest inclination and the bottommost screen having the greatest. As part of the machine’s full overhaul, the engineers at Mogensen performed extensive numerical simulations and tests to determine the ideal angles of inclination for the screens, maximizing the grading quality of the MSizer extend while maintaining its high throughput levels.

In addition, the fact that the MSizer extend features a design that effectively prevents blinding means that the need to clean its screens has been minimized. And to make things even easier, there are various effective screen cleaning systems available, including, for example, a pneumatic cleaning system. Moreover, the MSizer extend is available with an optional screen deck heating system that prevents screen blinding when dealing with bulk materials that contain residual moisture. The advantage? This makes it possible to eliminate an additional drying step for certain applications.

Finally, an extremely broad variety of screen inserts are available for the MSizer, making it possible to cover a wide spectrum of bulk materials ranging from food all the way to heavily abrasive materials such as quartz. The comprehensive range of equipment at the Mogensen Technical Center in Wedel, Germany is available for customer-specific hands-on tests.

New engineering design

The modern design behind the MSizer extend is the result of state-of-the-art simulation technologies and practices, including finite element analyses. One result has been the use of smaller motors, which yield significant energy savings of up to 20 %.

Another advantage of these smaller motors is the fact that they vibrate less, which means that the static and dynamic loads exerted on the steel structure, the production facility’s structural framework, and the machine base is reduced. The result? Lower steel fabrication costs when new construction is involved and minimized stress on existing infrastructure when existing buildings are used.

Despite all these changes, however, the MSizer maintains its compact and heavy-duty design. Its high availability has been improved not only by the updated design, but also by a series of enhancements.

Easy maintenance and seamless integration

When improving the MSizer extend’s ease of maintenance, the company’s engineers focused extensively on the requirements involved in real-life applications. Accordingly, faster screen changes, keying designed to prevent motors and electrical connectors from being swapped by accident, and new protective covers made of a composite all contribute to the ability to make changes in record time. Another noticeable detail in the new MSizer extend is the hexagonal design of its material outlets, which not only makes convenient assembly possible, but also enables users to easily replace wear plates.

This ease of maintenance also extends to motor installation. The MSizer extend’s motors must run in opposite directions and the new machine features a motor connection that prevents incorrect installation when motors are replaced, ensuring that the entire system will function properly. Likewise, initial machine assembly is also designed to be easy, with the unit being prewired and preassembled before delivery so that putting it into operation will simply be “plug and play” involving a single connection point and no specially trained specialist personnel.

In addition to this, a modular design makes assembly and disassembly easier and faster, and easily accessible inspection openings enable users to check that the machine is working properly during operation.

However, the optimizations to the MSizer extend are not just limited to its design and equipment. In fact, they include digital networking innovations that make the machine future-proof. One example is the optionally available electronic machine monitoring system, which continuously monitors vibrations and responds to abnormal operating states so that malfunctions can be detected in a timely manner and costly production downtimes can be avoided.

The bottom line

With its new MSizer extend, the Allgaier-Group has truly raised the bar when it comes to high-performance screening machines. This innovation is characterized not only by an even more compact design, but also by a large number of advantages: optimum availability, lower steel fabrication and facility investment costs for customers, smaller motors for energy-efficient operation, and low-vibration operation. Moreover, the machine’s screens and motors can be replaced quickly and easily, minimizing downtimes while the modular design makes assembly and disassembly both easier and faster.

Hall 4A / 315