Apullma stainless steel conveyor belt cart for unloading fertilizers and salts travels

on inverted V-rail

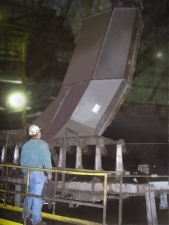

Bulk wagon load and unloading specialist Apullma is expanding its range of bulk unloading systems with the launch of a new, extremely robust conveyor belt cart for aggressive and abrasive bulk. Made entirely of stainless steel – including the chassis – and kept on track by a V-rail.

The new Apullma conveyor belt cart is available in steel or stainless steel. The stainless steel design is ideal for aggressive loads such as salts and fertilizers. Areas of application include transshipment points for bulk material producers, building material or stone dealers, freight forwarders and logistics providers who have their own siding and want to unload the wagons at any point on the track and – thanks to the robust and easy-to-lay profile rail – with minimum installation effort on site. As there is no need to build expensive bulk bunkers, there is also no need to provide wind and weather protection to avoid bunker cleaning before each unload process.

The main belt of the Apullma conveyor belt cart is flexibly adjustable and can therefore be adapted to specific unloading requirements – such as unloading onto trucks of different heights. The feed belt can be extended, adjusted in inclination and swiveled horizontally so that it can be positioned exactly below a wagon‘s unloading hatch without having to laboriously maneuver the wagon into position. The conveyor belt cart for V-rails is controlled via a user friendly remote radio control. It comes with an optional feature to store the position of the feed belt, which greatly speeds up repositioning between the hatches of the hopper wagons.

The design of the Apullma conveyor belt cart with V-shaped wheels on one side for moving in a straight line can be adjusted to individual user requirements. The V-rail conveyor that is already available in series production has a throughput of approximately 250 – 300 t/h including 50 % shunting time for fertilizers, and up to 700 t for comparatively heavier building materials. With faster maneuvering, higher capacities of up to 400 t/h for continuous unloading are theoretically possible. The conveyor belt of the cart has a standard length of 12 m. The chassis is 3 m wide and therefore constructed in such a way that the conveyor belt cart can be transported without special permission for extra-wide heavy loads, which makes it easier to move between locations. Individual configurations are available on request. Optionally, the conveyor belt cart is also available without V‑shaped wheels and in variants approved for driving on public roads.