Cloud-based solution for data-driven services and performance optimization

Schenck Process introduces CONiQ® Cloud

Schenck Process introduces CONiQ® Cloud

© Schenck Process Holding GmbH

With this initial release, CONiQ® Cloud covers data ingestion from edge devices, provides secure data storage within the cloud, and professional user and device management. The wide range of technologies and applications that can be connected to the cloud will open-up new functionalities for different machines. In its first version, it will focus on the application for vibrating screens and provide dashboards and functions to improve condition monitoring.

With CONiQ® Cloud, Schenck Process continues to add to its existing CONiQ® family. Extending its digital portfolio, it now offers:

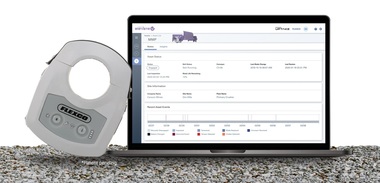

Cloud dashboard: An easy-to-use web dashboard brings KPIs directly to any laptop, tablet or mobile device, simply by using an existing internet connection. The design ensures improved user experience and quick assessment of essential performance indicators both for machines and individual processes.

Extensive service options: Data provided by the cloud allows experts to offer tailored remote services. It enables real-time condition monitoring and intelligent process control for output optimization and exact resource planning. The resulting transparency facilitates efficient management of consumables and spare parts scheduling.

Broad compatibility: CONiQ® Cloud guarantees data-processing from various sources. It is connectible to any customer system or other IoT clouds and directly compatible with Schenck Process’ CONiQ® Monitor systems.

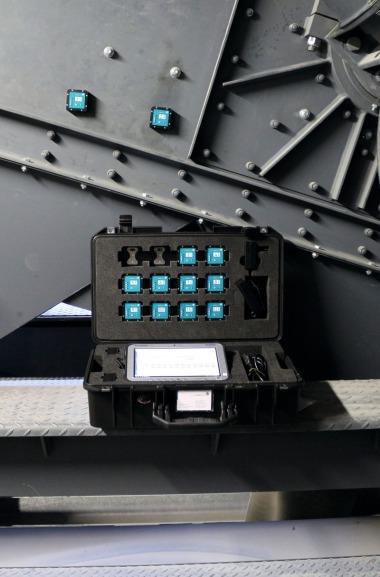

CONiQ® Cloud will be released with Schenck Process’ IoT edge solution CONiQ® Monitor which manages all sensors, performs edge analytics and securely pushes all relevant data into CONiQ® Cloud. The edge solution enables data ingestion by the local process control system, thus providing process critical information directly to plant operation and maintenance.

Asone of the global market leaders in industrial weighing and feeding applications, Schenck Process focuses on digitizing existing products and developing new digital services while combining technology and application processes in a smart and data-driven way.