Digital efficiency in two large iron ore export terminals in Brazil

Automation with BulkExpert™

Automation with BulkExpert™

© FLSmidth

FLSmidth has received an order for its BulkExpert™ digital solution from a customer in Brazil. The solution will fully automate the stockyard operation of two large iron ore shipping export terminals in the south of the country. BulkExpert is a digital solution that allows for the unmanned, fully automated and optimised movement of material handling equipment in dry bulk terminals. It does this by using a 3D laser scanning system, RTK-GPS technologies and state-of-the-art control software that processes proprietary algorithms to enable fully autonomous operation.

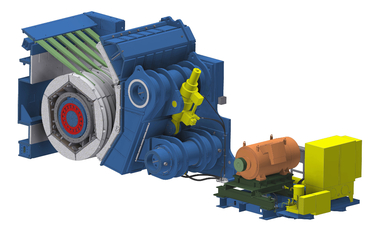

The order comprises a core digital solution and advanced automation for three stockyard machines at one port and eight stockyard machines at the other (including standalone and combined stackers and bucket wheel reclaimers). The solution will deliver several benefits to the customer, including higher throughput, greater efficiency and increased guaranteed performance. Extended machine life and reduced maintenance can also be expected due to lower stress on the machinery. The BulkExpert solution will be fully integrated with the customer’s own systems and will provide safer remote operations thanks to technical innovations like an enhanced anti-collision and collision-avoidance system. Elsewhere, quality management will keep track of all material movements in the stockyard, while a sophisticated material blending control will reduce quality deviations, enabling the customer to save valuable natural resources.