Gebr. Lödige Maschinenbau GmbH

Gebr. Lödige Maschinenbau GmbH is presenting itself at this year’s POWTECH with a new stand concept. As a special highlight a fully optimised tablet coater will be demonstrating state-of-the-art possibilities for mixing processes and related technologies in the core industries: chemicals, pharmaceuticals, food production and environmental technology.

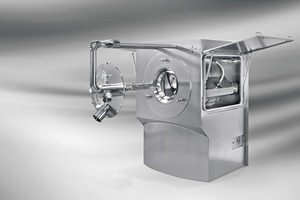

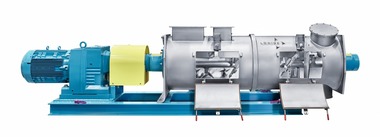

The new coater (Fig.) revolutionises the efficiency of coating processes and enables coating times that are 40 to 50 % shorter than with conventional solutions due to an innovative drum geometry combined with a special configuration of the installed nozzles. A continuously operating Ploughshare® mixer with a total volume of 900 l will be demonstrating a multi-stage, continuous overall process in chemical engineering: in practice no less than three continuous horizontal mixers of different sizes and design are used. Machines and systems are conceived individually for each customer and manufactured in Paderborn/Germany. Process technology from Lödige is used worldwide for processing solid materials, granulate, powders, dusts, pastes and sludges.

Hall 5; Stand 222