HAZEMAG Group

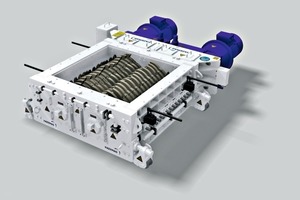

At bauma 2013 HAZEMAG Group will present several exhibits. With the Secondary Impact Crusher HSI 1414 (Fig. 1) HAZEMAG combines two successful impact crusher-series to a single one and thus increases the efficiency in the secondary crushing. With this new development HAZEMAG combines the advantages of two impact crusher series in a completely revised design and the approved claim for quality, ease of maintenance and cost effectiveness. For a minimization of the operating costs and an increase in efficiency a multitude of options is at customer´s disposal. The new HAZEMAG HSI series follows the principle of the platform strategy, which means: one housing – several options. The customer may opt between different impact aprons and rotor types. Hence HAZEMAG increases the crusher’s efficiency. Within the modularly designed platform the grinding path e.g. may simply and easily – even subsequently – be integrated in the machine.

The new HAZEMAG HSI series may be used for the secondary crushing of wear intensive hard rock as well as for low-wear soft and medium-hard rock. The fitting may be adapted to the respective case of application: for hard crushing solid wear-resistant high chrome casted components are used as lining material. For crushing soft to medium hard rock one may choose from different built-in components. The impact aprons and the optionally applicable grinding path of the HSI are each infinitely hydraulically adjustable by the push of a button. During the operation the hydraulic system keeps the impact aprons constantly in their adjusted position. In case of an overload-situation the impact aprons evade in a controlled manner, afterwards they immediately return to this initially adjusted position. Thus the danger of damage is minimized and the oversized grain fraction is limited. The HAZEMAG HSI series is characterized by a constant product quality and a high operational safety.

For the industrial beneficiation of primary and secondary raw materials crushing processes for the production of certain grain sizes, forms and surfaces or for the extraction of multi-component materials play a central role. The HAZEMAG Sizer HCS as well as the HAZEMAG Secondary Crushing Plant with Roller Screen and Feeder Breaker (Fig. 2) represent energy-efficient crushing without interruption. The method of action of the HAZEMAG Sizer HCS bases on a continuous generation of pressure between two counter-rotating rolls, so that the crushing – in opposition to the periodically working cone and jaw crushers happens without any interruption. The sizer‘s housing and drive unit are made up in rugged design. It is fitted with easily exchangeable wear parts. The direct drive consists of electric motor, fluid coupling and gear. The fluid coupling offers excellent protection against impacts and blows in a rough operation and thus serves as overload protection.

The crusher rolls for primary and secondary crushers are rolls with crushing rings which are fitted with exchangeable sizer teeth. The crusher rolls for secondary and tertiary crushers consist of shafts which are fitted with exchangeable crushing segments. One result of the specific geometry of shaft/crushing rings and the crushing tools, is an optimum tight fit, in order to resist the high crushing forces.

Hall B2; Stand 319/414

Outside area F23; Stand B/8