HOSOKAWA ALPINE

High throughputs at low energy consumption

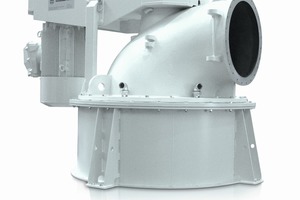

The system and energy efficiency are major factors when classifying mineral fillers. The low-energy classifier ACP 1250 is laid out especially for the production of fillers in the fineness range of d97 = 8…45 μm. Up to now, the amount of energy that the classifier requires in the case of classifier mills is around 30 – 40 %. The ACP 1250 reduces the specific energy consumption by a quarter. The ACP 1250 operates with an optimised classifying wheel that bases on the energy-efficient ALPINE NG classifying wheel principle. A cast iron housing from the MS classifier series ensures the requisite degree of robustness. Over and above this, the product routing of the ACP 1250 within the classifier was optimised so that even high throughputs can be reliably handled.

The ACP 1250 is designed to achieve medium fineness values and high throughputs and is suitable for use in a closed circuit with ball mills or as a high-performance final classification unit. At an air flow rate of 60 000 m3/h, the classifier exhibits a significantly reduced pressure drop of 36 mbar. In comparison with other systems, the minimised pressure drop of the ACP 1250 leads to a high energy efficiency – without reducing the performance. At the same time, the classifier is characterised by a good fines yield and a top cut ranging from 8 – 45 μm.

Robust and efficient classification of soft to medium-hard materials

HOSOKAWA ALPINE will be present at the POWTECH 2019 with a flexible solution for the ultrafine classification of different soft to medium-hard materials, namely the TTD classifier head. Fineness values to d97 < 3 μm at high throughputs can be achieved. The product line comprises a total of five models, meaning that there is a suitable machine for every requirement. The classifiers are operated either in circuit with ball mills or as stand-alone machines for classification or final classification.

The TTD classifier head was designed especially for the classification of industrial fillers as well as materials such as limestone, marble or chalk. The machine construction is correspondingly robust. The coarse material classifier is equipped, for example, with an air intake to permit additional product dispersion. Over and above this, the direct drive has a more powerful motor bearing. The robust classifier head makes not only reliable classification possible, but also operation in a particularly energy- and cost-efficient manner. The reasons: the classifying wheel is supported in bearings on both sides, the two fines discharges as well as the optimised feed product routing direct to the classifying wheel.

The flexible design of the TTD classifier head makes it possible to top-mount it on a grinding chamber. This combination results in the TDG jet mill. With this combination, extremely high fineness values are possible which cannot be achieved with conventional jet mills. Mineral powders, for example, can be ground to a fineness of d50 = 0.5 – 1 μm.

Hall 4a-233