Improved dewatering of sludge with a Leiblein vacuum belt filter

Better sludge dewatering with inclined plane

and vacuum

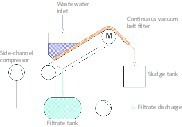

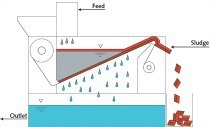

The continuous filter belt of the VBF with stainless steel filter belt – optionally available in plastic – is inclined. In the lower section, the sludge is fed to the filter over its entire width, in the upper section the sludge is dewatered. The filter belt retains more and more solids so that a filter cake is formed.

With the resulting increase in the flow resistance, the water level of the medium rises at the same time to a level at which the integrated float switch activates the drive. The belt with filter cake is drawn upwards, the stable covering of sediment formed under the influence of the slight negative pressure is scraped off. These special conditions are effected by an integrated side-channel compressor that continuously sucks air out of the filter chamber. The filter cake is collected in a sludge tank.

To continue sludge dewatering, the stainless-steel belt is cleaned with a brush roller and a rinsing system. At the same time, the clean filter plane at the end of the belt glides back into the feed section. As no filter cake has been formed, the water flows off more quickly, the level falls and the movement of the belt is interrupted again.

Sludge dewatering impresses in direct comparison

Based on a direct comparison with standard systems such as the chamber filter press, decanter centrifuge, belt filter press and filter bed, the Hardheim-based dewatering specialists have recognized that the Leiblein vacuum belt filter scores points with regard to many performance parameters in sludge dewatering. The aspects energy consumption, maintenance requirement and costs of acquisition alone were described as moderate, with the operating requirement being classed as very low. Moreover, the VBF automatically adapts to any fluctuation in the consistency, the composition and solid content of the filter feed, which enables largely trouble-free operation of the filter.

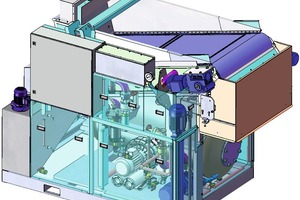

Compared to the high solids concentration achievable with the chamber filter press, the Leiblein technology does not quite match up, which, however, is made up for by the continuous feed, the absence of a buffer tank and unnecessary manual intervention for opening the press. The Leiblein system proves a compact sludge dewatering machine in which tanks, pumps and control system are already integrated, making it immediately ready for operation once the feed and discharge hoses have been connected and any auxiliary agents added. Additional plant components like reaction tank, feed pump, screw conveyor for the filter cake can be easily integrated into the control system.

The vacuum belt filter can be used in the process chain of Leiblein process water cleaning as well as a problem solver for sludge dewatering with other processes upstream.

Typical applications demonstrate versatile use

In the glass industry, a Leiblein inclined filter is used to sediment any particles from the sawing, grinding and polishing of flat glass. The sludge formed is pumped to the VBF and dewatered, and then the stable sludge disposed of. The process water contains not only material particles but oils and emulsions. With dosing of flocculant, better cleaning and dewatering can be achieved. In contrast to other dewatering processes, a very gentle dewatering is performed (flocs are not destroyed, fine particles are retained by the filter cake), effective filtration rates and low residual moisture contents still being achieved.

In many applications involving small to medium volumes of sludge, the vacuum belt filter offers significant advantages compared to conventional processes. Another example comes from the high-grade processing of plastics at a recycling firm. When the plastics are washed, contaminants enter the process water, which is then processed on an lamella separator. The separated contaminants are collected in a sludge hopper before being pumped to a VBF for dewatering. In this application, the firm does not use any auxiliary agents like, for example, flocculants.

Pilot-scale filters are the machines of choice

As the manufacturer reports, the effectiveness of the vacuum belt filter for sludge dewatering can be tested and future operating costs determined in a pilot trial. With this measure, including all the auxiliary equipment, at a small cost, the general suitability and the required size can be determined.

Moreover, other Leiblein components are available for pilot tests, with which not only the single process step of sludge dewatering, but the entire processing of waste water can be tested.

//www.leiblein.de" target="_blank" >www.leiblein.de:www.leiblein.de