Inclined filter replaces more and more old belt filters

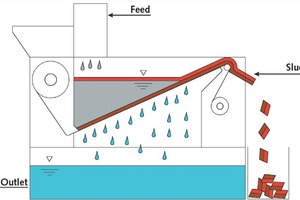

In its product range, Leiblein, the filtration specialist, offers an inclined filter that with its principle of operation clearly scores points in respect of efficiency, disposal, costs and quality. With filter cloths made of different materials and with a fineness from around 5-100 µm, the filter can be used to separate both filterable and floatable solids. Filtration rates of more than 50 m³/h per filter (depending on the solids load/viscosity of the liquids) can be achieved. This efficiency is based on the operating principle of the filter’s fleece bedding, which is inclined and performs filtration in the bottom part of the water chamber, while the filter cake formed is post-dewatered in the upper part. Depending on a certain level of liquid above the filter cake, a belt motor effects the upwards motion of the filter cloth. A scraper removes the dirt from the filter cloth, which is taken up again by a spool.

The resulting “fresh” cloth at the bottom of the belt, where filtration takes place, has a low flow resistance, which results in the decrease of the water level, the belt stops and filtration starts again. The automatic filter process on the incline from Leiblein ensures optimum utilization of the filter cloth. On the one hand, this is because of the feed from the bottom, which first covers the filter material with sediment, and second because the flotate together with the sediment is taken off further up on the inclination to the discharge.

In addition comes the full utilization of the entire width of the filter cloth as the filter lies flat on the inclined surface. In the case of certain filtration requirements – for example in grinding processes – the filter cloth can be easily reused. This results in lean operating costs, other advantages being the use of stainless steel (long lifetime), low wear (only gear motor, low maintenance) as well as easy supply of replacement parts with components of German branded quality. The Leiblein inclined filter is also good for the environment as with removal of the filter cake from the filter cloth, it can help meet the requirements of the German Closed Substance Cycle and Waste Management Act, which prescribes the separate disposal of materials.