Increased productivity and longer service life with sensor-based sorting technology from TOMRA

Among these activities was the ore sorting project, started in 2015 in collaboration with TOMRA Sorting Mining, with the objective of rejecting low grade material in coarse particle size. By separating sub-economic material before entering the more cost-intensive wet processing, the project would address the bottleneck at the wet section and improve productivity by increasing the feed grade. An added benefit expected from the project would be the longer life of the mine.

Three main factors indicated that sensor-based particle sorting for waste rejection would be effective at the San Rafael mine.

The high absorption of transmitting X-Rays of tin contained in Cassiterite

The structures of Cassiterite which are large enough to be detected by X-Ray Transmission (XRT) technology due to the way its mineralization occurs

The significant degree of liberation of sub-economic waste on the particle level that may be subject to sensor-based particle sorting

In order to assess the feasibility of the project, TOMRA conducted metallurgical tests on geological samples from San Rafael, followed by Performance Test Work. The tests showed the deposit of the mine to be especially suited for XRT technology due to the presence of 70 – 80 % of uneconomic particles that can be rejected over a wide size range, from 6 – 70 mm.

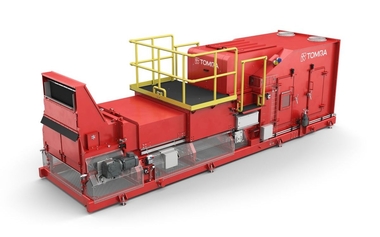

The project was approved and, in view of the significant economic potential, it was fast tracked and completed in just 14 months. TOMRA and its partner in Peru, which supplied and installed the XRT sorting system, worked closely with MINSUR throughout the six-month ramp up period.

The ore sorting project with TOMRA’s XRT system has delivered significant financial benefits from the beginning, with MINSUR realizing payback on their total capital expenditure in just four months. In 2017, it contributed around 36 % of MINSUR’s total production with about 6000 tonnes of tin.

The project’s impact on the San Rafael operation is contributing in several ways to a reduction in the mine’s capital and operating costs:

TOMRA’s XRT sensor-based ore sorting is converting uneconomic waste material into economic ore, as material below the cut-off for the main plant can be treated with lower operating costs and converted into reserves

Increased capacity in the main plant, from 2950 t/d before implementation to today’s 3200 t/d, as a result of the crushing operation at the XRT-sorting plant

Significant improvement in the overall recovery in the main plant, from 90.5 % to 92.5 %. This is because sensor-based ore sorting rejects particles with very fine mineralized Cassiterite that is too small for detection by the XRT system, resulting in higher grade and size of mineralization

Extended life-of-mine: today, about 24 % of the feed to the sensor-based ore sorting plant is contributed by low grade ore from underground

Elimination of liabilities through the treatment and proper disposal of 100 % of the stockpile

Decreased tailings disposal, as the sensor-based ore sorting system reduces the amount of waste by increasing the grade in the feed to the plant

The success of the project has demonstrated the high potential of TOMRA’s XRT technology, and as a result the company plans to include XRT sensor-based ore sorting as a possible process route in all future projects.