Integrated drive technology from Siemens enhances productivity

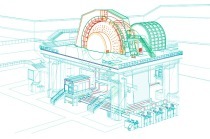

The Siemens Drive Technologies Division is delivering an Integrated Drive System for two new mills for the Toromocho mine in the Peruvian province of Yauli. The order comes from Minera Chinalco Per S.A., a subsidiary of Aluminum Corporation of China (CHINALCO). In future, two gearless mill drives and Sinamics cycloconverters will be used in the new production line with one SAG mill and one ball mill. Thus, one million tons of copper concentrate, 10 000 tons of molybdenum and four million ounces of silver oxide can be mined annually – even at an altitude of around 4600 m above mean sea level. Through the expansion of the mine and the resulting increase of the mining volume Toromocho sets to become the most productive mine in Peru.

The Toromocho mine in Morococha, Yauli province/Peru, is situated just less than 150 km from the capital city of Lima. The Minera Chinalco Per S.A. mining company would like to boost the mine‘s productivity with a new production line. Since the mining area for copper, molybdenum and silver is around 4600 m above mean sea level, special requirements apply to the mill drives. Not only must they be able to cope with the rugged environment in a mine, they must also fulfill the special requirements of the remote, difficult to access mine site topography.

Siemens will be delivering two gearless mill drives (Fig.) and water-cooled Sinamics SL150 cycloconverters to meet these special Toromocho requirements. In future, the 36-foot SAG mill of the new production line will be operated with a 13.5-megawatt drive. A further gearless mill drive with 22 megawatt output will ensure equally efficient and reliable driving of a ball mill with an inner diameter of 28 foot. Gearless drive systems are distinguished by their high efficiency and their low maintenance effort. Complex maintenance operations at an altitude of 4600 m can thus be avoided, which saves time and cost for the operator. The Sinamics cycloconverters are characterized by low switching losses due to their thyristor technology and also contribute to a high efficiency. Through the optimum interaction of the drive components a high availability of more than 99 % can be achieved.

//www.siemens.com/mining" target="_blank" >www.siemens.com/mining:www.siemens.com/mining