The heavy-duty solution for mixing and granulation of sinter material in the steel industry

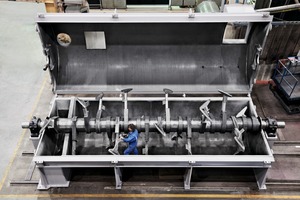

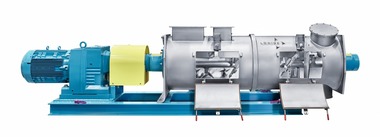

The heavy-duty solution for mixing and granulation of sinter material in the steel industrySummary: The mixing and granulation of sinter material in the steel industry is a heavy duty application that makes specific demands on mixing technology: Large quantities of extremely abrasive materials have to be processed daily. The example of Gebr. Lödige Maschinenbau GmbH shows how a high mixing quality, extreme wear protection and particularly high ease of maintenance can be realised on a large scale. The company has produced the largest intensive mixer in its 75 years of company history for use in an Indian steel plant: the KM 57000 SIN. This huge machine, measuring eleven metres in length and weighing 60 tonnes, has been equipped by the experts in mixing and granulation from Paderborn to the highest standards.

Iron sinter is required for producing pig iron in a blast furnace. The raw materials for sintering consist of iron ore, limestone, coke, return fines and binder. The various materials are fed in the correct ratios to the mixer from the respective storage bunkers, and are mixed and granulated before they are ignited in the ignition hood of the sinter strand. The material is subsequently transported on by the sinter strand while the sintering process continues to burn down through the sinter bed. The quality of the raw sinter mix achieved in the mixer and the granularity of the mix are very...