Maintenance-free level measurement

MBA Instruments GmbH considers numerous advantages in terms of measurement to accrue from the use of the stepper motor instead of the conventional synchronous motor. Rotation speed, torque (sensitivity), change in the direction of rotation and signal trigger time are just some of the parameters that are adjustable in the stepper motor. Since these parameters also exert an impact on one another, the engineers at Quickborn have transposed their expertise to parameter adjustment combinations, aggregating them in ten different sets. Only the torque remains separately adjustable, as this ploy additionally offers a number of advantages in terms of flowability and the density of the bulk material.

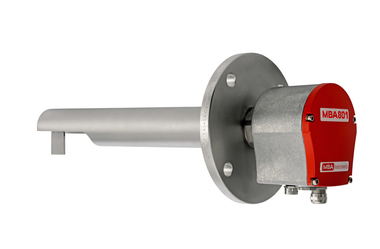

The entry-level-priced model MBA888 goes one step further. In this instance, a single setting respective to each parameter was selected and defined in a specific adjustment set. Settings can thus no longer be changed. Even the housing is completely sealed; the connection cable and signal cable are connected to the device with a M12 plug connector. Thus, for the first time, devices are being launched on the market in a „plug and play“ version (Fig.). The entire MBA800 rotor series was subjected to vibration and shock testing at 29 g. The devices are thus unaffected by vibration. The features of the MBA888 are characterized by further technical refinements. The unit head is so small that it can also be deployed in loading devices and in downpipes. The change in the direction of rotation makes deployment possible directly in the flow of the bulk material, as a signal is emitted only if the paddle is blocked in both directions.