New approach for tailings management in mining

Metso is driving this change by introducing a new concept for the dewatering, handling and reprocessing of tailings. Designed to maximize water recovery and reduce the footprint of tailings dams or eliminate them completely, Metso Tailings Management Solutions provide a long-term solution for mining companies looking for a viable approach to their tailings management and end-of-mine strategies.

There are a huge amount of tailings discharged and lying in legacy dams. Today, only about 5 % of tailings are dewatered while roughly 70 % of the mines are located in countries where water scarcity is considered as an issue. The way tailings are handled can have a long-term impact on the mines‘ economic efficiency as well as on the well-being of the surrounding environment and communities.

“Metso views dry filtered tailings as the most viable and long-term solution for tailings management: it helps in recycling significantly more water to the concentrator, while enabling mines to reduce their freshwater footprint when compared to traditional tailings impoundments. Furthermore, the risk of tailings dam failure could be completely avoided by dewatering and dry stacking the tailings,” says Niclas Hällevall, VP of Beneficiation Solutions, Mining Equipment business area. “Contrary to conventional belief, dry tailings are also much more CAPEX and OPEX efficient compared to wet or thickened tailings.”

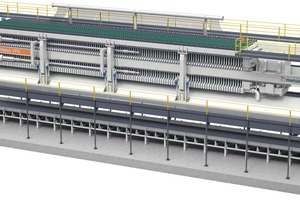

The Metso VPX™ filter can handle difficult-to-dewater tailings, because it has up to 25 bars operating pressure. This enables up to 90 % water recovery. The Metso VPX™ is also equipped with a fully electromechanical drive system and no hydraulics, making it one of the safest solutions on the market. With its modular design, the Metso VPX™ filter is scalable as well as easily transportable to the site in standard containers.