New cross-conveyor system for the F60 overburden conveyor bridge at open cast mine Welzow

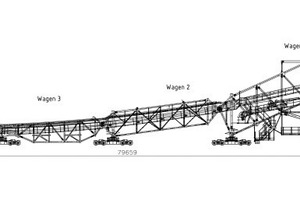

In August 2014, TAKRAF GmbH received an order from Vattenfall Europe Mining AG for the supply and installation of the new cross-conveyor system for the F60 conveyor bridge in the open cast mine at Welzow-Süd in Brandenburg. The scope of services included the fabrication respectively conversion of hopper cars and chassis as well as the scrapping of system components which would no longer be used. The special challenge of the project was the tight schedule. Thanks to the commitment and the long-standing experience of all experts involved in VATTENFALL and TAKRAF, the system could be delivered after ten months, as planned.

Production started immediately after the award of the contract, and the first parts arrived at the site after five months. In close coordination of fabrication and erection team, all operational obstacles were managed to meet the demanding schedule. The hopper cars were were relocated from April 2015 onwards. Thus an important milestone with regard to the mine operation was reached on time.

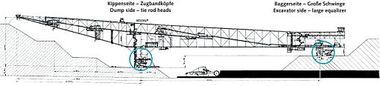

Until end of June 2015, the cross-conveyor system had been further assembled. The scrapping, conversion and adaptation work, which was carried out in parallel, was executed with the help of a TAKRAF transport crawler with a load capacity of 250 t was used, which had been supplied by TAKRAF to VATTENFALL earlier. The next milestone was in May 2015, again on schedule, when the complete conveyor bridge was moved by about 10 m in order to couple the new cross-conveyor system to the bridge. The scope of work also included the renovation of the lubrication system as well as corrosion protection at the construction site.

All personnel involved in the project team in the fields of engineering, fabrication and site erection worked closely together, thus enabling the successful realisation of the contract within the pre-determined schedule, benefitting from the expertise developed over many years in complex reconstruction and modernization works, as e.g. changing the tension tie rods on the conveyor bridge in the Jänschwalde open cast mine. The cross-conveyor system was able to be completed in June 2015. After three days of commissioning of the conveyor bridge complex by experts from Vattenfall, the conveyor bridge went back into mine service.

TAKRAF is already working on another project at Vattenfall, i.e. changing the large bogie and the roller table at the F60 conveyor bridge at open cast mine Nochten.

$(LEhttp://