New products for dry screening

Besides its established products for wet screening such as the Stack Sizer®, which can consist of up to five screen decks stacked on top of each other to make up a compact screening unit with high capacity, Derrick Corporation has recently developed new products for dry screening. These not only new screen designs, but new polyurethane screening surfaces for dry screening.

A key new development in screening machines is the transfer of the Stack Sizer principle to dry screening. Fig. 1 shows a dry screen with four screen decks that operate parallel to each other. This enables a multifold increase in capacity despited limited space. The required power for the machine is, as typical for Derrick designs, very low at 2 x 1.8 kW. The dynamic loads that the machine transfers into the steel structure are also low so that the screen is also suitable for retrofitting in an existing facility. The machine can be supplied both as a side- or end-tensioned screen. One modified screen model can hold up to three double-deck screen frames in one support frame. All screen decks can be visually inspected even during the screening process. For this purpose, inspection flaps are installed on the side to make each deck accessible. The new machines are completely dust-tight and equipped with a central extractor system.

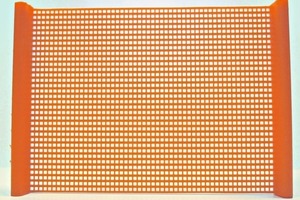

Key advances in tensioned screening surfaces have been made in the development of fine polyurethane surfaces for wet and dry screening. In wet screening it is possible to use PU surfaces with slotted apertures up to 45 µm with 27 % open screen area. For dry screening, special non-blinding polyurethane surfaces up to 106 µm can be supplied. The latest development in fine polyurethane screens tries to avoid the disadvantage of slotted surfaces. The development of polyurethane square-mesh panels for fine screening to (currently to 0.6 mm) is an example of this development. Fig. 2 shows a square-mesh surface with 1 mm apertures and around 30 % open screen area. This screen design too features tapered apertures to prevent blinding.