New technologies and trends in the (inter)national mineral-resources industry

The emphases during the first day of the event were, above all, on the following topics: the global minerals market, supply of mineral resources, the presentation of international mining projects and a research cluster into the preparation of complex Sn-W ores.

Dr. Martin Wedig, the director of the FAB, Berlin, welcomed the attendees and opened the event. The first speaker, Prof. Magnus Ericsson, of Luleå University of Technology, Sweden, started with a paper entitled “Global metal markets – is there light at the end of the tunnel?”. He emphasised, in particular, the necessity for more exploration work if future needs for mineral resources are to be met.

The next address, by Dr. Frank Leschborn, was also concerned with the availability of mineral resources, focussing on the topic of “Aspects of future global supply of mineral resources”. The need for mineral resources and energy is set to rise continuously, against the background of the growth of the global population. The increasing change in the energy industry and the rising amounts of regenerative energy sources being used will necessitate innovative mineral resources, which will have to be recovered and prepared. This will present great challenges to the respective technologies in terms, in particular, of costs and productivity.

International mining projects, exploration in Germany’s Erzgebirge range, tungsten mines in Spain - these are only a few of Deutsche Rohstoff AG’s activities which were examined. Dr. Thomas Gutschlag focussed in his paper, entitled “Deutsche Rohstoff AG – experience in mining at home and abroad”, on other interesting projects in the USA, Canada and Lithuania.

The paper “Mineral-resources supplies involving conflict-mineral ores: Reality, boundary conditions and CSR, focussing on the example of tantalum ore” by Christian Cymorek, of H.C. Starck GmbH, was devoted to an extremely many-faceted topic. What are the internal and external boundary conditions in this field, what proofs of origin are there, how does the duty of due care look – all questions which were discussed, taking the obtainment of tantalum feedstocks as an example.

Due care - or rather “due diligence” - was also the keyword for the next presentation, bearing the title of “Technical and economic due diligence in mining projects - experience drawn from practice”, and given by Nikolaus Linder, of Fichtner Water & Transportation GmbH. The term “due diligence” signifies the careful examination and analysis of corporate entities.

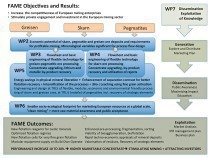

Dr. Wolfgang Reimer, of the Freiberg Geocompetence Center, and Mirko Martin, of G.E.O.S. Ingenieurgesellschaft mbH, discussed in their paper the “Preparation of complex Sn-W ores citing the example of the FAME project – routes for cluster research at federal and EU level”. Here, the acronym “FAME” stands for “Flexible and Mobile Economic processing technologies”. The project focuses on routes for technical improvement and the boosting of efficiency in the exploitation and preparation of complex low-grade ore deposits. Such deposits constitute domestic European reserves of tin, tungsten and important associated minerals.

On the second day of the event, the focus was on underground mining, preparation, and methods for the analysis of minerals and ores.

David Horner, of the TU Bergakademie Freiberg University of Resources, examined the subject of “Real-time mining – the challenge of automation of underground mining”. To illustrate his subject, Horner compared the processes of classical mining with those of real-time mining. His project, in the context of “Horizon 2020” - the European Union’s framework programme for research and innovation - concentrates, above all, on the problems of data-acquisition and data-communication in mining.

“Potential applications for down-hole geophysical measuring methods in prospecting for ores and rare earths” was the topic selected by Sebastian Schmidt, of BBi – Brunnen- und Bohrlochinspektion GmbH, for his presentation. The question of whether the use of gamma-spectroscopy in boreholes and neutron activation of specimen materials would permit deductions concerning the composition of the mineral material was investigated. Measurements have shown that elements can in principle be successfully detected by means of down-hole measurement. Further data is now needed to permit expansion of this method, however.

The next address, by Dipl.-Ing. Christoph Göbel, of Outotec GmbH & Co. KG, transported the audience to more remote regions: “Iron-ore preparation projects in Iran - an experience report”. Preparation methods must, in some cases, also be able to adapt to climatic conditions - and dry preparation methods are especially appropriate in desert regions.

In his presentation on the “Recovery of Technology Metals – Critical Review and Perspectives”, Dr. Horst Märten, of Umwelt- und Ingenieurtechnik GmbH Dresden (UIT), Heathgate Resources Pty. Ltd., Australia, focussed, in particular, on the potentials and benefits of in-situ getting of deeper-lying deposits. The advantages of extraction wells, for example, include shorter lead times and reduced development equipment needs for the ore fields – i.e., getting of metals from the surface, without the creation of an underground infrastructure – and the relative environmental friendliness of this procedure.

“A new comminution and liberation quality for ores and steel-mill slags using energy-efficient VeRoLiberator® technology” was showcased by Prof. Dr. Gregor Borg, of PMS GmbH. He emphasised that this new technology permits extremely high comminution rates and liberation of minerals for a relatively low energy input.

The next two papers examined international problems in the minerals-getting industry: “Graphene production by means of direct electrolysis of graphite-containing black shale electrodes from northern Sweden”, given by Dr. Georg Hochwimmer, of TALGA Resources, Australia, and “Laser-ablation ICP-MS micro-analysis of metal elements in ore minerals as support for the international exploration and mining industry”, presented by Prof. Dr. Reiner Klemd, of the Geo-Center of Northern Bavaria, Friedrich-Alexander University of Erlangen-Nürnberg (Nuremberg).

The two-day series of papers concluded with an address by Dr. Lutz Krakow, of Dr. Krakow Rohstoffe GmbH, under the title of “Mineral-resources efficiency in the brick industry – background and practical examples”. The brick industry, in particular, is subject to high cost and innovation pressure. The use of clayey residues may provide a way out.

The participants had the time and the opportunity to discuss what they had heard and to make further contacts and new networks during the breaks and at the evening event held on the first day, which started with a beer-tasting session at the “Brauhaus Goslar” pub-brewery. This excellently organised event presented all participants with a genuinely broad range of topics focussed on the mineral-resources industry.