Sandvik LH621i for large scale underground production and mine development

The Sandvik LH621i sets the industry standard in the 21 tonnes underground loader range. The Sandvik LH621i has been built on proven technology inherited from its market leading predecessor, the Sandvik LH621, and now it enters the market equipped with further improved features. With superior hydraulic power for fast bucket filling and drivetrain power for high ramp speeds, the Sandvik LH621i is designed to quickly clear tunnel headings for rapid advance rates. Engineered with operator and maintenance personnel safety in mind, the rugged loader offers long component lifetimes and low costs per tonne.

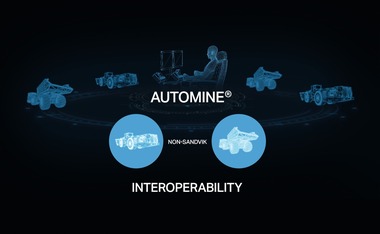

For easy product health monitoring and faster trouble shooting, the Sandvik LH621i features the latest Sandvik Intelligent Control System and My Sandvik Digital Services Knowledge Box™ on-board hardware as standard. The equipment has been designed automation ready, which makes the unit flexible, enabling Sandvik‘s AutoMine® installation also as a retrofit just in a couple of days. To improve comfort and productivity in manual operation, significant improvements have been made to the operator‘s compartment, as the Sandvik LH621i features a new more spacious and ergonomic cabin with increased visibility and a 7" touch-screen color display, among others.

In the engine compartment, a fuel efficient 352 kW Stage II / Tier 2 engine deliveries powerful thrust for fast bucket filling and high-speed tramming for high productivity. A new, more powerful 375 kW Tier 4f / Stage IV low emission engine option is available with the use of Ultra Low Sulphur Diesel Fuel. The diesel engine brake in the Stage IV / Tier 4f engine provides better control of vehicle speed downhill, minimizing brake and transmission overheating and brake wear. Further, SHARK™ Ground Engaging Tools (G.E.T.) are available on a wide range of bucket sizes, optimized for loader productivity and extended bucket service life.

Sandvik‘s i series loader and truck family now forms a full house of intelligent equipment with two loaders and three trucks: Sandvik LH517i, Sandvik LH621i, Sandvik TH545i, Sandvik TH551i and Sandvik TH663i.

rocktechnology.sandvik