Saving one crushing stage in the production of high-grade chippings

In Roetz in the Upper Palatinate region of Germany – not far from the Czech border – the long-established building materials company Georg Huber (owned by Josef Rappl GmbH & Co. KG) is managed by the brothers Josef and Georg Rappl in the third generation. Following opening of the first ballast works in Winklarn in the 1940s, the Boehmischbruck Quarry came in the early 1980s (Fig. 1) and later in the 1990s came the Duernersdorf plant.

At the Winklarn works (Schwandorf district in the Upper Palatinate), there is amongst other things a stationary Metso HP200 cone crusher that produces 0/32 chippings in the second crushing stage (Fig. 2). “We have only been working with it since last year – with much less wear on the crusher tool and higher availability,” Georg Rappl says. The company used to operate an impact mill, the running costs of which rose significantly towards the end. “For the old machine we needed three sets of impact bars per year – with the new cone crusher we buy a set of crushing tools which will surely last two years,“ he forecasts. Besides producing chippings, Georg Huber processes the volcanic rock serpentine at an asphalt mixing plant in Winklarn. For road construction mineral aggregate is also produced.

If you drive another half an hour, you reach the granite quarry in Boehmischbruck, which covers an area of around 10 hectares. Here too Georg Rappl and his brother have changed a few things. For production of high-grade chippings, they have replaced three Krupp crushers with two new stationary cone crushers from Metso, which do the same job much more efficiently. Both HP3 crushers have been running since spring and are coordinated with each other to deliver an optimum final product to meet all requirements (Fig. 3): in two crushing stages – “fine” and “extra-fine”, the first of the two crushers processes the 2/56 size; the second crushes the pre-produced material from 0/22 mm to 0/2, 0/5, 0/8 and 0/16 mm as required. After the HP3 “Fine”, the oversize is screened to feed it back to the first crusher.

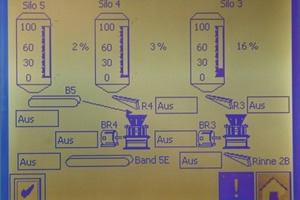

For control purposes, the filling levels of the silos and the crushers were intelligently interlinked with each other after installation (Fig. 4). If one silo runs empty, the first crusher automatically stops. The control system measures the power consumption after upper and lower limits have been defined previously. If the power consumption exceeds the upper limit, this counts as a sign that the crusher load is too high.

To combat the overload, the cone crusher automatically opens the gap. If the power consumption falls below the lower limit, the crusher responds in the opposite way and closes the gap. This leads to automatic wear balancing of the crusher tool. While the “Fine crusher” is equipped with automatic control, for the second crusher for “extra fine further crushing”, remote adjustment from the control centre is supported, although the crusher can be controlled in automatic mode too (Fig. 5). “The interesting thing about the IC7000 Advanced Control system from Metso is the synchronization of the filling level reading, feed and comminution,” says Georg Rappl (Fig. 6). “Even instructing the operator in using the control system was very easy.”

The throughput rates of the new cone crushers from Metso vary between 200 and 240 t/h or 1000 t high-grade chippings per day (Fig. 7). As the crusher tools of the new crusher are not cast, they can be changed over within just three hours. The plant in Boehmischbruck produces 40 % high-grade chippings, 30 % ballast and around 30 % frost protection material. Buyers for the material not processed in the company’s own mixing plant are construction companies, concrete plants as well as national and local authorities. In the next development stage in the east and south of the quarry there is still enough potential for operation. In the third ballast works Duernersdorf, the product range breaks down similar to that in Boehmischbruck. And, of course, it is certainly not out of the question that Georg Rappl will introduce more economically efficient processes and the associated technical changes there in the near future.