Systematic proportioning and loading

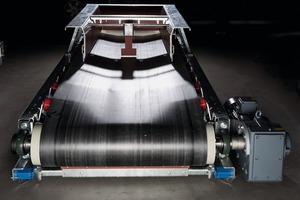

For more than 60 years WÖHWA Waagenbau GmbH has specialized in high-quality proportioning devices for the volumetric and gravimetric proportioning of bulk solids. WÖHWA will present the new generation of the proportioning conveyor belts 10.2 RD, Regular Duty, and 10.3 HD as well as 10.4 HD, Heavy Duty. Amongst other things, they distinguish themselves by a high ease of maintenance. All standard proportioning conveyor belts from WÖHWA can be supplied with removable covering hoods to avoid dust emissions. They can also be delivered with dedusting connections at the transfer points to the collecting belt. This good accessibility enables a quick and easy replacement of the belts and idlers despite the complete enclosure and safe dust protection. All connections at silos, dedusting systems and at the collecting belt have been standardized.

One-stop loading systems and dispatch automation

WÖHWA offers all core components so that the proportioning and loading operations as well as the dispatch technology run smoothly. The formulations with the desired quality are achieved by means of the proportioning and loading control system PCS 35 for loading onto the truck, train or vessel. The corresponding grain-size distributions in the silos are taken into account for the formulations meeting the legal grading curves. It is always possible without any problem to connect the proportioning and loading control system with the weighing data processing from WÖHWA. Loading lists, disposition lists, a multistage user administration and statistical functions support the users during their daily work. Furthermore, remote maintenance, automatic data securing, loggings, operating hour meters as well as a status monitor offer comprehensive service functions.

The belt weighers with automatic follow-up determination ensure the desired quality on the vehicle with any loading. Due to the interconnection with the proportioning and loading control system PCS 35 from WÖHWA, the loading process is stopped at the right time and, consequently, overloading or underloading is avoided.

The WÖHWA dispatch automation enables a smooth vehicle service. A registered order can be handled by the driver himself without the interference of other people.

The combination of proportioning devices, loading control, weighing technology and automatic dispatch from WÖHWA ensure the right quality and quantity of the bulk solids on the vehicle. From the entrance weighing machine up to the delivery note, all relevant interfaces are within the WÖHWA loading and dispatch system.

Stand: B2.410

$(LEhttp://