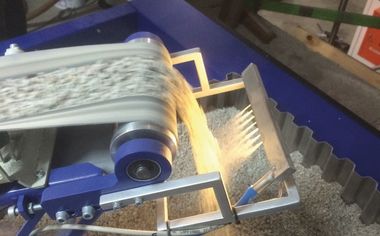

The Titan – V22 dust-binding machine

The dust-binding machines from NEBOLEX Umwelttechnik GmbH are fully automated high-performance turbines with different launch ranges and diverse application fields. A component system is used with which water is atomized through special nozzles containing a ceramic liner at a pressure of 3 – 5 bar. Atomization is achieved solely through the water pressure. State-of-the-art valve technology for regulation of the water throughput determines the size of the single drops of water. This is an important criterion for the quality of dust binding. The smaller the single drops of water, the greater is the overall surface area of the water. In this way, substantially more dust particles swirling in the air are bound and the dust formation is minimized.

The patented nozzle head is axially incorporated into the turbine and achieves a distinctly higher launch range than comparable nozzle configurations. The targeted water mist beam is less susceptible to wind. Several nozzle rings can be switched on and off as needed. Thanks to the booster pump, the machine can also be used with a switched-off turbine. The easy control by means of radio remote control, the vertical tilting angle 0 – 52 ° and a rotation angle of at least 350 ° optimize the turbine.

Dust-binding machines are available in different sizes. Depending on their application area, the various models ranging from V7 through V12S to V22 all have their advantages. Accordingly, almost any dust problem can be solved. Nebolex Umwelttechnik can be contacted regarding questions about the individual machines and their optimal usage, as well as any repair and maintenance work that may become necessary. A comprehensive spare parts depot in original equipment manufacturer quality provides prompt support in case of malfunctions. Maintenance contracts for the supplied dust-binding machines ensure long-lasting safety and reliability.

//www.nebolex.de" target="_blank" >www.nebolex.de:www.nebolex.de