The sinter plate filter for higher

temperatures

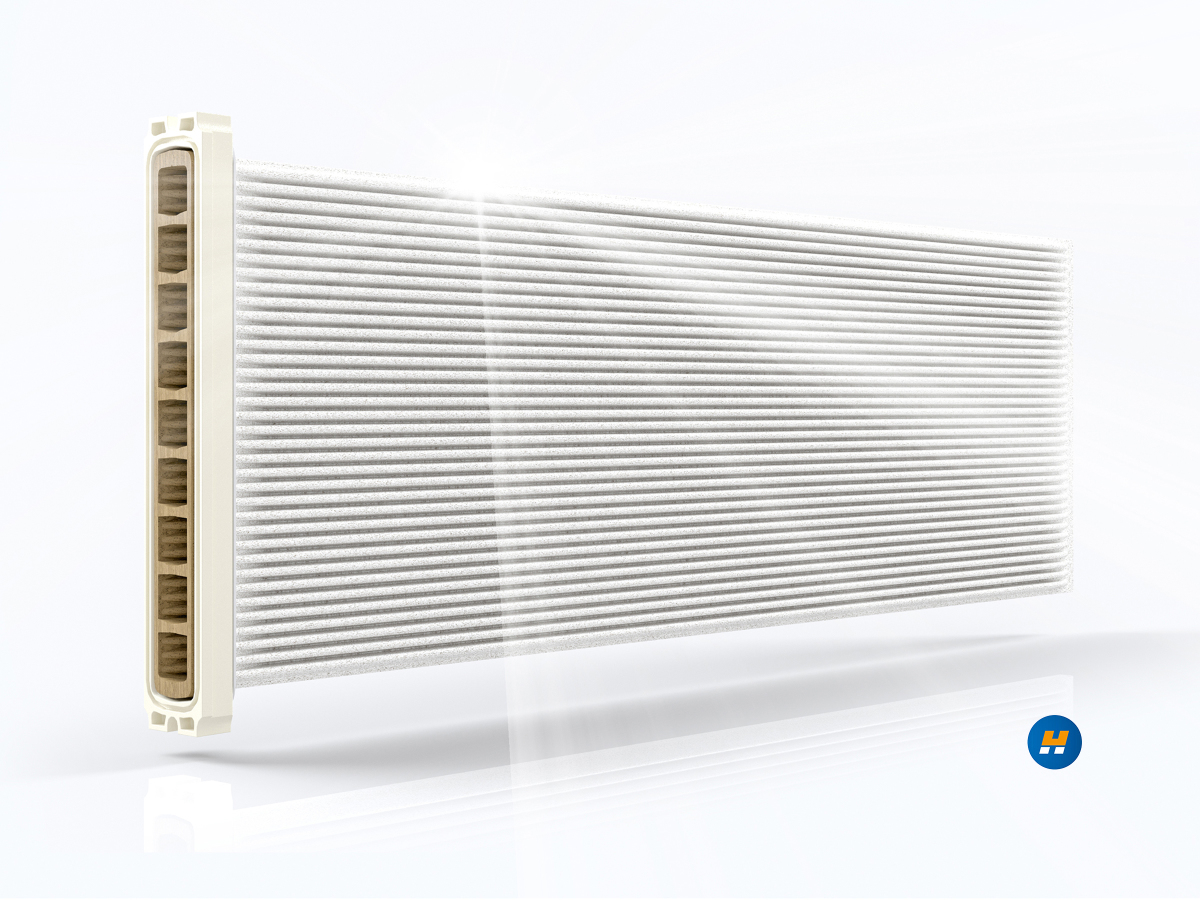

Newly developed Herding BETA filter element

Newly developed Herding BETA filter element

© Herding Filtertechnik

Pure surface filtration ever since

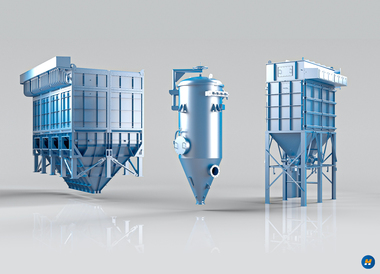

The basis of the technology for many decades has been consistently pure surface filtration, achieved with rigid-body filter media. The central component of the online cleaned filter systems is the proven Herding® sinter plate filter. In the surface pores of the rigid-body filter media, a coating with a formulation tailored to the application is embedded homogeneously and firmly as a filter-active layer. This combination of an exceptionally robust sintered structure and the coating embedded in it makes the sinter plate filters so effective.

The particle spectrum to be separated accumulates on the filter surface during the filtration process, and there is no affinity for irreversible embedding of fine particles in the filter base body. Consequently, there is also no tendency to clog the filter medium. Even abrasive substances are reliably separated without damaging the homogeneously embedded filter-active layer. The coating remains intact over the entire life cycle and, according to experience, undamaged.

Moreover, the rigid sintered matrix is not subject to the risk of permanent flexing of other filter media and thus does not exhibit any filtration-related wear and tear. This results in the very long service life of Herding® sinter plate filters, which experience has shown to be in excess of 15 years. Constant pressure losses and thus constant operating conditions ensure the necessary workplace safety throughout the entire life cycle.

Well-proven properties now also up to 160 °C

The classic Herding® sinter-plate filters with PE-based matrix base materials can by definition be used at operating temperatures of up to 70 °C and, as a thermostabilized variant, up to 100 °C. The new developed and patented Herding BETA, based on a sintered matrix made of PPS, now allows the use of all known features of the classic sinter-plate filter up to a continuous operating temperature of 160 °C.

The new filter medium represents a very versatile filtration technology, which is extremely resistant to chemical attack and also hydrolysis, as well as having a range of 1 – 10 with regard to pH resistance. Absolutely constant operating conditions due to the above-described pure surface filtration are also possible with the Herding BETA for operating temperatures up to 160 °C. In addition, the new filter medium can be operated with reduced pre-cleaning pressure; significantly lower operating costs thus significantly increase energy efficiency. Like the classic sinter-plate filter, the filter medium is absolutely fiber-free and thus ideal for contamination-free material recovery.

Extensive development work by Herding’s own R&D department has resulted in extensive pilot phases in various application areas with diverse types of filter systems in which the Herding BETA has been put through its paces. Examples include various dryer applications, biomass incineration plants, extraction from rotary kilns, glass tank dedusting and high-temperature filtration behind mill systems.

Hall 5, stand L17