When it comes to asphalt recycling, it’s all about the perfect process chain

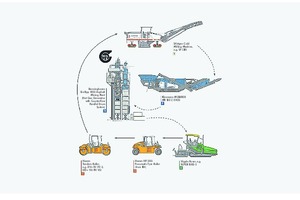

This also means that millions of tons of asphalt are being removed – a job primarily performed by cold milling machines. They are the first link in the process chain, which continues with crushing and screening plants as well as asphalt mixing plants in the next step and ends with the reclaimed asphalt being repaved by pavers as part of the new mix. Machines designed to work together, innovative processes, and state-of-the-art technologies all have a major impact on the efficiency of this process chain. Smooth processes make it possible to increase the cost-effectiveness and sustainability of asphalt recycling.

The Challenge: Increasing the feed volume of RAP

In many countries, virtually every truck that transports asphalt mix on a site has at least some recycled asphalt on it. In Germany alone, for example, a quarter of the total asphalt produced in 2018 (41 million tons) contained RAP (10.5 million tons). With a total of around 12 million tons of asphalt pavement removed last year, this represented a recycling rate of 87 %.

Recycling old asphalt is an economic imperative in order to conserve natural resources. As a result, the industry is constantly looking for solutions to optimize the processes within the asphalt mixing plant. One of the main approaches is to increase the volume of reclaimed asphalt pavement used in all of the different recipes produced using “hot and cold” processing technologies. Using the maximum amount of old asphalt not only protects the environment, it also positively affects asphalt mix prices.

In the traditional parallel flow recycling method, the temperature is limited to 130 °C due to the exhaust gas emissions, but the exhaust gas temperatures are physically higher, which leads to increased energy consumption and the need for additional dedusting. In order to achieve a mix temperature of 160 °C, white mineral must be overheated in this case.

The Solution: The counterflow method –

recycling rate of 90 + X%

Unlike conventional parallel recycling drums, in a recycling drum with hot gas generator the recycled material is heated indirectly using the counterflow method, meaning that the material in the drum flows towards the heat source. This makes it possible to achieve higher material temperatures while simultaneously reducing the exhaust gas temperature. The outflow temperature of 160 °C corresponds to the temperature of subsequent processing, while the exhaust gas temperature lies above the dew point at approx. 100 °C.

The entire process is only possible by using a hot gas generator, because direct firing would burn the recycled material and make it unusable. The burner, hot gas generator, recycling drum, extraction hood, and the recirculation and exhaust air system are all designed to work in perfect harmony. One positive effect is that the white mineral no longer has to be overheated, which results in a significant reduction in energy consumption. Recycling using the counterflow method massively reduces emissions (as required by Germany’s Technical Instructions on Air Quality Control regulation) and – depending on the quality of the recycled material – achieves recycling rates of 90 + X %. This makes an investment in the equally green and efficient technology particularly attractive.

And the technology becomes even greener when the upstream process steps – processing the particle-size distribution curve (PSD curve) and milling the asphalt – are implemented using state-of-the-art processes and technologies.

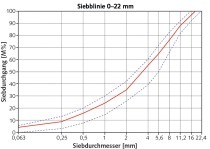

Screening plants: Ideal particle-size distribution curve increases amount of RAP added

The maximum theoretical amount of RAP that can be added to the mix depends largely on its PSD – or, to put it another way, on the quantity, size, and composition of its constituents. As a result, one goal must be to align the PSD curve of the crushed RAP as closely as possible to the desired PSD curve of the final asphalt product. This is where mobile screening plants come into play. They ensure that the mixing plants are able to directly process up to 80 % of the reclaimed asphalt (milled material). This significantly reduces process costs compared to post-processing all of the milled material.

In the case of complete post-processing, i.e. also of the remaining oversize grain, impact crushers equipped with a secondary screening unit would also be used.

Intelligent milling for cost-effective and sustainable recycling

First, however, the RAP must be recovered by removing individual layers of the road structure. By removing the asphalt in layers using cold milling machines, the milled material can be fed into the material cycle for reuse separately for each type of mix, depending on its structural suitability and its qualitative properties. The selective recovery of the surface course, binder course, and base course alone offers significant environmental and financial advantages.

If intelligent milling technology is also taken into account, it increases the cost-effective reuse of the milled material in the asphalt mixing plant even further. This is largely due to the cold milling machines’ load-dependent water sprinkling system. In this context, the water used to cool the picks varies depending on the engine load and milling speed. Water consumption can be significantly reduced by automatically activating the water system when the milling drum is in use or by switching it off when the milling operation stops. Specifically, this can cut water consumption by up to 20 %. As a result, the service life of the picks is extended, the cold milling machine’s water tanks have to be filled less frequently, and downtimes are shorter. This not only pleases the milling machine operator, but also the master mixer in charge of the asphalt mixing plant. They benefit from the low water consumption because it means the milled material has a 3 – 4 % lower residual moisture content per ton of asphalt. Without the use of state-of-the-art milling technologies, the residual moisture level would be higher.

The formula applicable to the drying process required to produce the new asphalt in the asphalt mixing plant is simple: Material that is 1 % drier saves 1 liter of heating oil per ton of finished asphalt during subsequent processing into recycled mix – as well reduced CO2 emissions due to the process requiring less energy.