When joints must not come apart

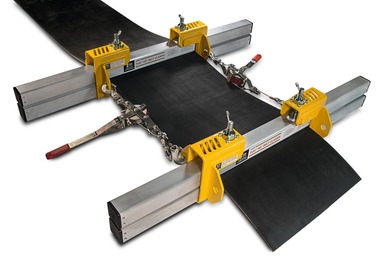

With the Rivet Hinged mechanical connectors for use in surface and underground mining, rivets penetrate the fabric inlays in the conveyor belt without damaging the fibres. They are fitted from the top of the belt. They ensure high tensile strength and distribute load uniformly across the width of the belt. As the rivets are offset, this solution is also suitable for older belts which are already showing signs of wear.

The connectors are flat in design, thus improving the approach for cleaning systems and reducing contact with side sealing profiles and return rollers. The system therefore wears more slowly and the joint holds for considerably longer. This enables users to increase the productivity of their conveyor systems as they have fewer breakdowns and reduce maintenance work. The rivets used in the connector system are offset and are provided with pilot nails. Their specially shaped heads and the anvil plate of the installation tool ensure a well formed rivet. The same hammer blows that the fitter uses to set the connecting elements also press the connector plates into the surface of the belt. The system therefore achieves a high tensile strength and distributes the load uniformly across the width of the belt.

The user can choose between different connector sizes depending on the place of installation. “R2” is a combination of two teeth and two rivets. This solution is suitable for medium-duty conveyor belts. Flexco provides the R5-1/2-SE version for heavy-duty conveyor belts such as those used in underground mining. This version is suitable for conveyor belts with a strength of up to 1250 N/mm and is available in galvanised steel. The R6-SE version is even more hard-wearing. Also designed in galvanised steel, it is suitable for conveyor belts with a strength of up to 1400 N/mm. The Flexco range also includes the Type RAR8-SE for single and multi-layer belts up to 2500 N/mm. All sizes are resistant to corrosion and chemicals. The rivets are optionally available in steel or stainless steel.

Flexco provides a range of portable electric tools for even simpler and faster installation. These are small, light-weight and ergonomic to use.

$(LEhttp://