Conveyor “Rules of Thumb”

This article examines the need for training conveyor operators and maintenance personnel by discussing the many informal design axioms that have developed over the years, otherwise known as “rules of thumb”. These rules have been developed by trial and error or from qualitative observations, often decades ago, and are routinely applied via specifications and by designers.

The topics picked for discussion – materials, skirtboards and tracking – will correlate to continuing problems in the handling of bulk materials by belt conveyor, often contributing to a lack of understanding and leading to addressing symptoms rather than root causes. Perhaps the only advice for conveyor design that has remained true is: Design for the worst-case conditions. But the reality is that often insufficient funding or engineering time is allocated to make the needed design changes to ensure safe and profitable operation.

There are numerous design generalizations that are accepted as truisms and seemingly require no proof due to their long-standing use in conveyor fabrication and operation. This begs the question: If these rules are proven to address common problems, then why do we still have all the issues of chute plugging, belt damage, dust and spillage when operating bulk material handling conveyors?

The variances in recommendations indicate that it’s easy to make mistakes unless the designer has solid, real-world knowledge in bulk material handling and can make educated assumptions when applying the rules. With the “old salts” who developed and handed down these rules long gone or fast retiring, there is a need to provide knowledge to the younger operators and maintenance personnel to avoid the trial and error associated with applying many of the handed-down design rules. Training based on a combination of industry experience and engineering will greatly improve design decisions, resulting in higher productivity, fewer safety incidents and reduced unplanned outages.

Historical design axioms

Many of these design principles undoubtably are the result of the early years of conveyor use and were developed by trial and error. Others emerged in codes developed in the early 20th century due to catastrophic equipment failures or as a result of being clearly correlated to injury risks or industrial disease outbreaks. Some had their engineering basis in testing done for early design manuals, but the original data has been lost. Yet the truisms live on. Then each industry and even each location developed their own rules, which became written into company specifications based on somewhat successfully treating symptoms rather than root causes.

There are often differences in rules by industry and many of them have no real engineering basis, instead being based on doing things the “same as before.” Since the modern conveyor was developed in the early 1900s, much has changed in conveyor belt construction, capacities and regulations. Conveyors are still sources of pollution and accidents, so it seems clear that “same as before” just isn’t good enough. The rules selected for discussion in table 1 are just a few of many common conveyor design guidelines that often contradict each other.

Material size

As high concentration ore bodies are depleted, the remaining bulk material needs more processing to remove refuse and size the material for processing. The cost of raw materials also drives processors to accept lower grade materials with a higher percentages of fines. When the quantity, quality or sources of the bulk material change, the design must anticipate new handling challenges. It may be that “nominal lump size” is the biggest lie in bulk material handling, as the actual lump size in production is typically much larger than the design specification. This discrepancy in lump size from specified to actual is often due to adjusting crushers or screens to increase production, from gradual wear or from longer maintenance intervals.

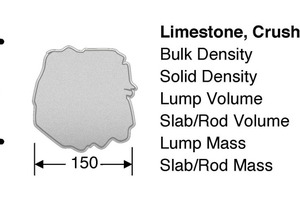

The lump size and % of fines provide guidance on selecting the belt width and then the skirtboard width and height. In Table 1 the references state that the lump size is to be considered 2 to 3 times the nominal or specified lump size. The lump size also influences idler selection due to impact forces. Picking the maximum lump size also depends on how the material tends to fracture – into lumps or slabs. It may well be that a slab is much longer than 2 to 3 times the nominal size, while at the other extreme, lumps may tend to be more spherical.Understanding the material, its properties and behavior is critical not just for idler selection, but for many other considerations such as chute size and slope. Just because experience shows that on one conveyor limestone flows well on a 50 degree chute slope, for example, doesn’t mean material from another pit or seam will flow down the same chute.

Bulk materials are hard enough to handle when consistent in size, physical properties and percent of fines. In Fig. 1, if the bulk density of 1440 kg/m3 is used rather than the solid or specific density of 2700 kg/m3, the mass used for idler and impact cradle selection would be almost 50 % underestimated, almost guaranteeing premature failures. For a slab or rod shape, the error could be significantly more than if using the nominal lump size. Lump or slab mass is a direct variable inputted into the idler and impact cradle selection methodologies. Correct maximum size and mass calculations can also affect belt selection. As the percentage of fines increases, the size of the lumps that can be tolerated on narrower belts also increases. In this example, 150 mm lumps and 10 % fines, for a material with a 30 degree surcharge, can be handled on a 900 mm belt, whereas if the cargo was 100 % lumps it would require a 1600 mm belt.

Skirtboards

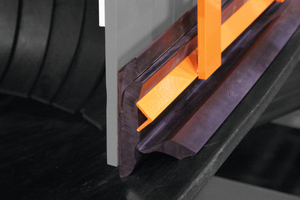

Skirtboard width and length guidelines were developed long before dust was a concern, most likely developed by observation and experience to determine sufficient height to contain the turbulent material long enough to allow it to settle into a stable profile after the belt is loaded. When covers started being used to control dust, there likely weren’t any changes to the height or length guidelines. Instead, the same general rules based on either belt width or belt speed continued to be used, expecting better results. Gradually it was recognized that the velocity of the air in the skirtboard enclosure had to be controlled to reduce dust emissions. At about the same time, suppliers and engineers began paying more attention to the wear liner and skirtboard sealing details to reduce leakage and spillage.

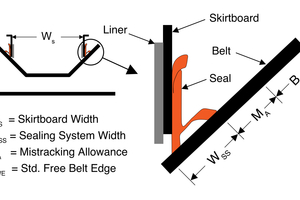

For the width of the skirtboards, most specifications follow the Conveyor Equipment Manufacturers Association (CEMA) recommendation of ⅔ of the belt width for most materials or ½ belt width for free-flowing materials, while the International Standards Organization (ISO) does not make a specific skirtboard width recommendation. CEMA and ISO have different free belt edge formulae for the distance between the loaded material profile and the edge of the belt. The free edge distance beyond the skirtboards is to prevent spillage outside the loading chute due to belt sag between carrying idlers. The free belt edge is often confused with the amount of belt edge necessary in the load zone for sealing systems and belt tracking. CEMA provides some guidance on skirtboard height based on lump size, but not for dust control.

Examining all the factors that go into an engineered loading of material on the belt would require a lengthy discussion of its own. The ⅔ of belt width rule is not generous enough on narrow belts and too generous on wider belts. ISO addresses the free belt edge with two formulae, one for belt widths under 2000 mm and one for wider belts. In addition to lump size, a main consideration for the skirtboard width is the space needed for the many different types of sealing systems, and to accommodate expected belt mistracking, because most belts mistrack far more than the commonly specified ± 25 mm allowance on a standard pulley face.

Fig. 4 illustrates that more than just the free belt edge must be accounted for in determining WS, the skirtboard width. It is generally accepted that WS is the inside dimension of the skirtboard uprights. If the wear liner is of significant thickness, such as cast iron or rubber blocks, the thickness of the wear liners should be considered in skirtboard spacing for their effect on conveyor capacity. Sealing system designs vary significantly, so the adequate edge distance in the load zone depends on the actual dimensions of the sealing system specified.

Belt Tracking

Theoretically, a properly installed and aligned conveyor system using a belt within manufacturing tolerances, with square splice(s) and center loaded should track without the need for training idlers. If most of the training idlers are tied off, it indicates that either they are ineffective or the belt must be constantly re-centered to compensate for structural and component misalignment or belt damage. Too many training idlers can interfere with each other and often make tracking worse. The guideline of installing training idlers a standard distance apart regardless of the quality of the installation and operation does not consider whether they are even needed or how much correction each training idler can generate. Sometimes more is less.

If the belt doesn’t have good contact with the training idlers (≥ 50 %), the poor contact can’t create enough frictional correction forces to overcome the belt stiffness and move the belt toward the center. It’s the same situation when knocking idlers to try to track the belt. Over-adjustment for tracking causes bottom cover wear and consumes more energy than one might think. Training idlers cost more than standard idlers and may be adding unnecessary expense with little benefit.

For a start in locating training idlers, the most critical positions are before the belt enters the tail pulley, after the loading zone, before the belt discharges and before the belt enters the takeup. Portable and underground conveyors may require more training idlers because of the installation tolerances or distortion of the structural alignment when portable conveyors are moved. Most belt tracking problems are related to misalignment of the structure, pulleys and idlers, not the absence of enough training idlers.

Conclusion

There are many inputs required to make a safe and productive conveyor that are not included in the general design rules. Unless the personnel dealing with conveyor issues have a basic understanding of how to treat root causes rather than perpetuate temporary fixes, problems will almost certainly continue. With the retirement of many experienced operators and mechanics – and the difficulty in finding new workers – it becomes critical that new employees understand the basics of conveyor design and operation. The homegrown “we’ve always done it that way” solutions frequently treat only symptoms and not root causes.

Today, there are many options for non-commercial conveyor training. Many companies offer in-person classes or virtual training. Some firms use real-time video conferencing with cell phones to show the actual problems and discuss solutions “live” one-on-one. With the increased emphasis on dust control and safety, using these “same-as-before” rules probably isn’t going to mitigate the dust emissions or provide adequate spillage control, resulting in workers’ unnecessary increased exposure to respiratory disease or safety hazards from cleaning. The most effective approach to training examines a plant’s specific conveyor challenges and helps operators run safer, cleaner and more productively by treating the root causes of its problems. The one axiom that still rings true: “If you think education is expensive, try lack of knowledge.”

Literature

[1] Belt Conveyors for Bulk Materials, 7th ed., Conveyor Equipment Manufacturers Association

[2] Crushing Plant Layout and Design Considerations K. Boyd 2002

[3] Army Corps of Engineers/NIOSH RI 9698

[4] OCC Belt Analyst Training May 2015

[5] Mining research contract report (February 1987); Bureau of Mines Open File Report 2-88, p. 22; Dust Control Handbook for Minerals Processing; Contract No. J0235005; Martin Marietta Corporation. Martin Marietta Laboratories

[6] Conveyor Equipment Manufacturers Association, Belt Conveyors for Bulk Solids, 7th ed. Fig. 4.2

Author:

R. Todd Swinderman, CEO Emeritus, Martin Engineering, Neponset/USA

R. Todd Swinderman joined Martin Engineering in 1979 as an Engineer in Conveyor Products, and has served as V.P. and General Manager, President and CEO, as well as Chief Technology Officer and Technical Director. He holds more than 140 active patents in 12 different countries. In his work with CEMA (the Conveyor Equipment Manufacturers’ Association) he has been instrumental in developing consistent standards to improve the safety and productivity of conveyor systems and components.

![Lumps vs fines and belt width [6]](https://www.at-minerals.com/imgs/1/7/6/3/7/6/9/tok_deab1a701b40187ad7aa65ba89b05ade/w300_h200_x600_y776_02_Training_Article_Fig_2-71b9ddad75228f59.jpeg)