How conveyor trough angles affect skirt wear

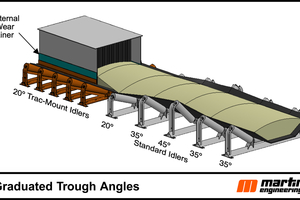

Belt conveyor trough angles are based on precise decisions made according to several operational factors. Material size, the way it settles when loaded (angle of surcharge), and how it centers when the full trough angle is achieved are all factors that need to be considered both in the initial design and during retrofits.

The selection of the conveyor belt trough angle is also a compromise between the belt width, the skirtboard width, liner wear, throughput and the desired reduction in spillage. The balancing of these variables is important for reliable and safe operation over the long term. Failure to examine this issue may result in lower capacity, increased liner wear, excessive spillage and belt damage.

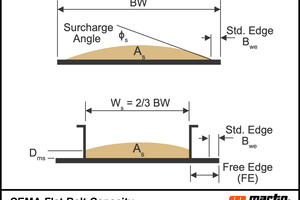

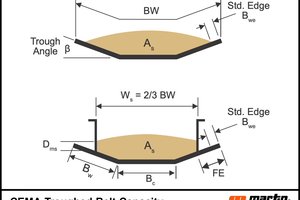

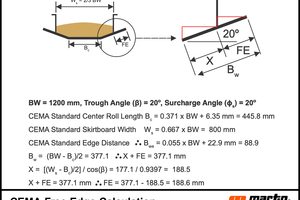

The CEMA geometry

In Chapter 4 of Belt Conveyors for Bulk Materials, 7th edition published by The Conveyor Equipment Manufacturers Association (CEMA), there are dimensionless ratios developed so that any...