Ilmenite producer purchases magnetic disc separator

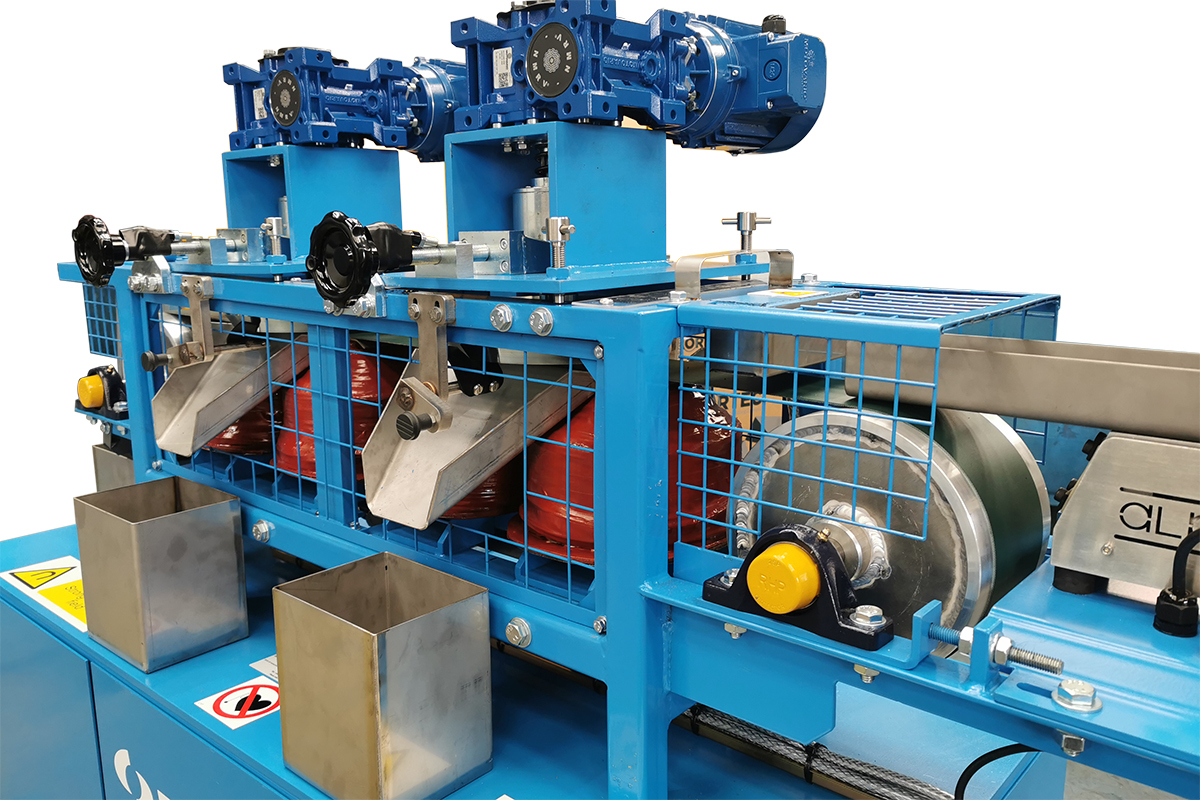

1 2-stage Magnetic Disc Separator (MDS)

1 2-stage Magnetic Disc Separator (MDS)

© Bunting

Ilmenite occurs as disseminated grains in basic igneous rocks or as larger ilmenite-magnetite or ilmenite-hematite segregations in gabbros and anorthosites. Ilmenite is commonly recovered from heavy mineral sands deposits where the mineral is concentrated as a placer deposit. The world’s largest ilmenite producing countries include Australia, South Africa, Mozambique, Canada, and India. Norway is the largest European producer. High-intensity magnetic separators recover and concentrate the weakly magnetic ilmenite from other non-magnetic minerals. For a dry process plant, many mining companies use the Magnetic Disc Separator.

Magnetic Disc Separators are used to process a wide range of industrial minerals including coltan (tantalum ore), beach sands, tin-ore, abrasives, and quartz for glass manufacturing. The Magnetic Disc Separator (MDS) is a separation system equipped with up to three independently working discs, which generate magnetic field strengths up to 14 000 Gauss. The high magnetic forces generated by the MDS enable the extraction of paramagnetic particles from a free-flowing, dry product stream (100 μm – 1.5 mm).

2 The high magnetic forces generated by the MDS enable the extraction of paramagnetic particles from a free-flowing, dry product stream

2 The high magnetic forces generated by the MDS enable the extraction of paramagnetic particles from a free-flowing, dry product stream

© Bunting

The mineralogy of an ilmenite deposit dictates whether the process route is dry or wet, with a preference to dry due to the reduced environmental challenges of initially sourcing water and the management of wastewater. The ability to adjust the magnetic field of the discs in a Magnetic Disc Separator enables the mineral processor to tune the separation to produce a specific grade of ilmenite. In operation, each Magnetic Disc is set at a specific magnetic field to separate a selected range of minerals in accordance with their magnetic susceptibility.

The laboratory-scale Magnetic Disc Separator at Bunting’s Customer Experience Centre in Redditch/UK is used to assess the magnetic separation capabilities on a wide range of mineral deposits. Globally-based mineral processing companies send material to the UK, where Bunting’s mineral processing engineers assess the optimum magnetic separation techniques to achieve a specific separation objective.