Energy efficiency overview

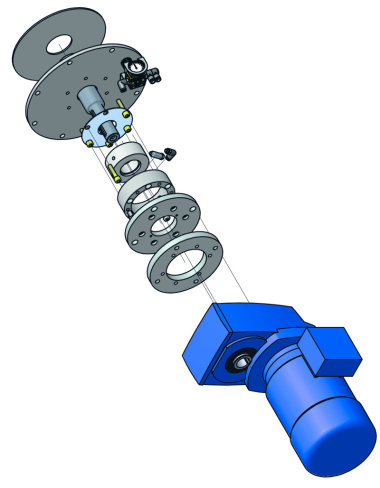

The Sizer software from the Siemens Drive Technologies Division is an engineering tool for planning drive applications with Sinamics. The new Version 3.4 of the Sizer engineering software (Fig.) from Siemens offers, in addition to a load-dependent energy consumption calculation, a drive conversion program for automatically generating energy-saving drive versions. Energy management is becoming more and more important in industry due to mounting energy costs, stricter environmental protection requirements and increased efforts to comply with certification in accordance with the international standard for energy efficiency EN16001. More than 50% of the base load of a machine is consumed by equipment units such as coolant and lubricant pumps, infeed and conveyor units and compressed air or sealing air. It is therefore worthwhile conducting a detailed energy analysis of the drives involved and an energy comparison to discover whether significant savings in consumption could be achieved with a different drive constellation.

Siemens AG, Nürnberg (D), Tel.: +49 911 895-0,