Bunting has acquired Gloucestershire-based powder milling and blending specialist Pilamec

30.03.2022Bunting has acquired Gloucestershire-based powder milling and blending specialist Pilamec. Pilamec further broadens the Bunting product portfolio.

Bunting is a global manufacturer of magnet and magnetic products serving a wide range of industrial sectors. The Bunting European engineering and manufacturing facilities are in Berkhamsted and Redditch, both in the United Kingdom.

Two of the ball mills at Pilamec

Two of the ball mills at Pilamec

© Bunting Magnetics

Since becoming a limited company in 1976, Pilamec has developed a reputation as a leading specialist supplier of materials and size reduction services to amongst other things the chemical, metal and ceramic industries. At their Gloucestershire operation, Pilamec processes a wide range of materials including, but not exclusively, a large variety of Ferro-Alloys, Silicon Metal, Graphite, Boron, Ferro Phosphorus and many more metal types. They also supply a wide range of Traded Metal Powders in both small and large quantities.

Pilamec specialize in providing batch dry milling, screening and blending of organic and inorganic minerals for companies in industries as diverse as mining, refractories, foundries, recycling, and ceramics. The materials handled range from metals, slags to non-toxic chemicals, with investigation and test of any product, of any type, needing size reduction.

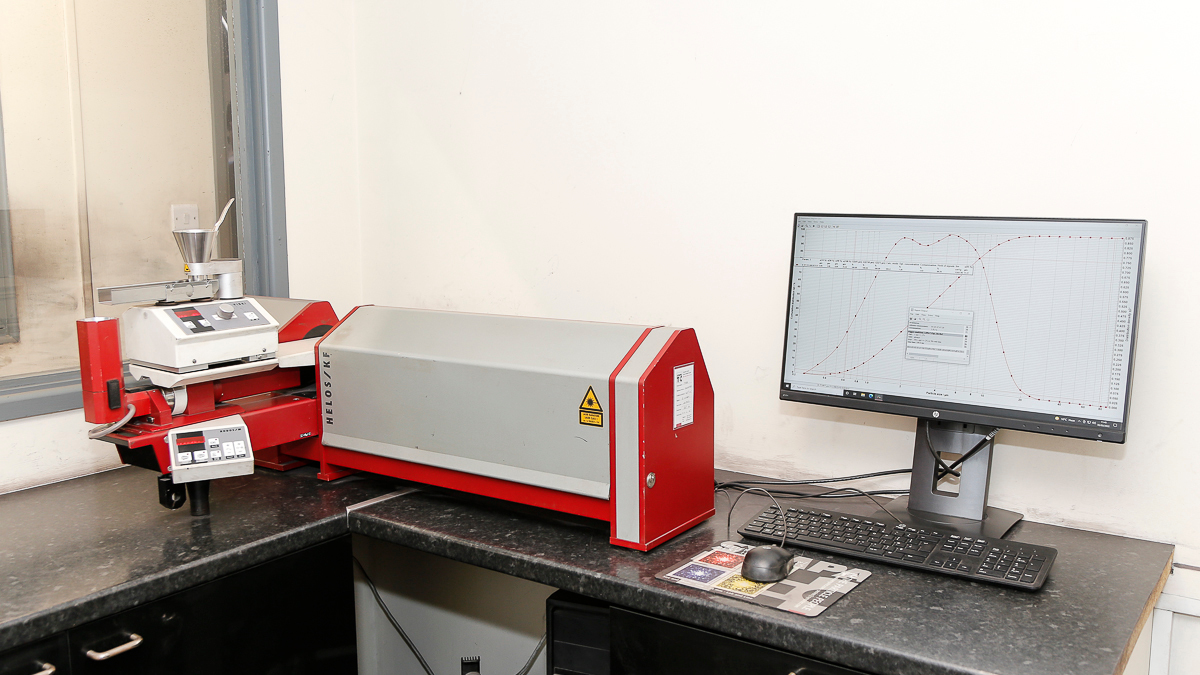

Particle Size Analyser in the Pilamec Laboratory

Particle Size Analyser in the Pilamec Laboratory

© Bunting Magnetics

The processing operation includes different types of milling, crushing, blending, screening and bagging. This has gained Pilamec a reputation of being able to advise suitable solutions to solve difficult problems through their experienced technical team. Projects have included producing silicon metal powder with extremely low particle size distribution, milling ferro alloys to tightly controlled particle sizing and densities, and processing, to granular/powder form, inorganic materials used in the construction industry.

Within their in-house laboratory testing facility, a Laser Particle Size Analyser enables extremely accurate particle size analysis, with distribution graph information for both internal analysis and for sharing with customers. Additionally, Pilamec’s technical capabilities extend to test sieving by manual means and powder density. This complete service assists in the accurate presentation of finished product results to customers.

Pilamec works closely with customers on development projects, using a Ball Mill to size reduce small quantities (20 kg) of product. Such controlled tests provide key information for further development of a bulk processing application.

For the ceramics sector, Pilamec regrinds waste generated during the ceramic manufacturing process to produce customer specific sized material for reintroduction into new customer blends thus reducing the amount of waste going to land fill. “Pilamec is a successful and well-respected company with great potential for growth,” explained Simon Ayling, Bunting’s European Managing Director. “Through our Berkhamsted operation we already supply magnet materials and the Pilamec acquisition expands our range of materials, processing capabilities and markets.”

www.buntingeurope.com