Metso launched the Spider crowder upgrade, offering superior froth management in large flotation cells

31.01.2024Metso introduced to its flotation portfolio the innovative Spider crowder upgrade, designed to address the challenges posed by large flotation cells. Given that flotation operates as a continuous process, ensuring the highest level of equipment availability and efficiency is paramount. The new technology promises superior froth management, safeguarding enhanced metallurgical performance, energy efficiency, and improved process control when installed with a Metso Center launder.

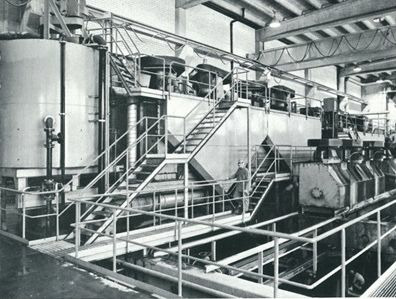

© Metso

© Metso

“We are excited to introduce this groundbreaking solution to the challenges of large flotation cells. This innovative technology is set to elevate froth management to new heights, ensuring optimal performance and efficiency. Furthermore, the easy installation of the solution improves employees' safety during equipment upgrades and maintenance,” says Christian Cardoso, Product Manager, Mechanical Flotation Services, Metso.

“The Spider crowder upgrade represents Metso’s innovative design with several process and customer benefits. The solution optimizes air flow rates, potentially reducing air blower energy consumption. This not only contributes to environmental sustainability but also results in significant cost savings over the long term,” says Guillermo Bermudez, Product Director, Flotation Services, Metso.

The quick installation process requires little to no modifications. The latest upgrade has been seamlessly engineered to be compatible with existing cells. The customizable, modular design ensures safe and easy tank access for efficient maintenance.

Flotation technology has played a pivotal role in Metso’s history for over five decades. Through subsequent advancements in the company’s evolution, Metso has significantly influenced the trajectory of mechanical flotation technology and helped to propel the industry forward.

Metso’s developments in flotation cell technology enable upgrading and retrofitting of older flotation equipment for enhanced performance. These advancements not only extend the lifespan of existing equipment, but also align operations with environmental and safety standards, ensuring long-term viability and compliance.

More information about the Spider Crowder upgrade and Center launder is available here .