Zero waste top of the agenda for CDE

15.06.2022CDE, one of the leading suppliers of sand and aggregate wet processing solutions for the natural processing and waste recycling sectors, have revealed their Hillhead 2022 product showcase – to include R4500 scalping unit, AggMax log-washer, and counter-flow classification unit.

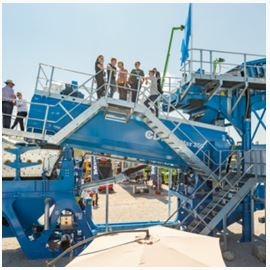

CDE's R4500 scalping unit

CDE's R4500 scalping unit

© CDE

Over their 30-year history, CDE have been engineered for zero waste with their wet processing solutions at the forefront of the evolution of sustainability across both natural processing and waste recycling. CDE collaborate with customers to create solutions that maximize the use of natural resources in the quarrying industry while extracting the valuable resources contained in waste streams in the recycling industry.

Alongside their Hillhead product showcase, CDE professionals will be joined by representatives from customers Peel NRE, part of Peel L&P. Peel NRE are at the heart of the nation’s activity around clean growth and the circular economy – helping the UK achieve net zero by 2050 and supporting regions in their actions to achieve climate emergency targets.

The company is currently working with CDE to embark upon a new venture called NRE Aggregates, which will be a vertical integration within their current business. During the show the Peel NRE team will share more about the upcoming C&D waste recycling project at Port Salford, in Greater Manchester, and plans for creating sustainable aggregates.

Equipment on display will comprise CDE’s R-Series primary scalping unit (R4500), AggMax log-washer, and counter-flow classification unit (CFCU).

The R4500 was created to handle the most troublesome materials, including heavily clay-bound mineral and waste materials, offering high-energy screening of material and oversize removal before it enters the AggMax log-washer for scrubbing and classification.

The AggMax technology is engineered to operate in the toughest of conditions to maximize product yield from the most abrasive and clay-contaminated feedstocks. Combining feeding, scrubbing, screening, and sizing, on one chassis, the AggMax is suitable for a variety of material streams – sand and aggregates, overburden, scalpings, C,D&E soils, utility arisings, muck away, and trommel fines.

The CFCU provides an effective system for the removal of lightweight contamination from fine material fractions. Its unique features provide sand classification by mass and density where water is used to suspend particles at the cut point. The CFCU also provides the added benefit of being able to tailor the final sand gradation specific to its end use, eg transforming the most difficult feedstock and waste streams into high-quality concrete specification sand.

Visitors will have the opportunity to see the plant up close as they are guided, by CDE experts, around the equipment that will be installed at sites across the UK for customers Ace Liftaway (CFCU), Peel Group (R4500), and Scott Bros (AggMax).

Commenting on CDE’s attendance at Hillhead, David Kinloch, director of business development for the UK and Ireland, said: “The equipment we will have on display at Hillhead will highlight the benefits of CDE technology in contributing to a customer’s environmental aims and commercial goals. We will discuss how these innovations are being applied by leading organizations globally and in the UK, with those we work in partnership with available to share their experience.”

He continues: “We will be presenting three innovative pieces of CDE technology that demonstrate our commitment to engineering excellence, and to ensuring our customers are investing in superior-quality plants that contribute to creating a better world, one tonne at a time. A large number of the UK & Ireland team from our business development, engineering, project delivery, and aftercare departments will also be available to share further insights about how our products help customers immerse themselves in the evolution of sustainability within their sectors. We are looking forward to marking our anniversary of 30 years of CDE. During this time, we have been co-creating with customers to deliver collaborative, imaginative, and unique wet processing systems, with over 2000 successful projects. We look forward to celebrating this at our first major UK exhibition since the beginning of the pandemic and coming together with those attending the event – from existing customers to new connections.”

Kieran Tames, director of development for Peel NRE added: “This equipment will turn construction and demolition waste into materials which will be used to build a multi-modal freight facility and distribution park at Port Salford and other construction sites across Greater Manchester. It will contribute to a circular economy and will be capable of recycling up to 240 000 t/a of construction waste.”

Stand A9