Using VisionLink to assess fuel consumption and maintenance work

It was back in the year 2000 that Caterpillar started offering companies the possibility of transmitting information in Cat machines by means of internal sensors and a transmitter. The system permanently transmits its own GPS position, start and stop times, motor load (idling/load) and other operating states. Ernst Krebs GmbH & Co. KG based in Neumuenster/Germany makes use of this function and has had its new machines equipped with the latest, internet-based fleet management system VisionLink from Caterpillar. The data used to be transmitted via satellite to a server. With the new hardware, the data is transmitted by means of the faster mobile communications technology. This enables simpler, more efficient and faster evaluation of the data. Users do not need their own IT for this, just the Internet and activation of the function at Zeppelin. All new Cat machines, which went into operation at Ernst Krebs in mid-2010, were ordered with VisionLink at the Zeppelin‘s Rendsburg branch (Fig. 1). These include the latest investments such as four Cat 962H wheel loaders. In addition came two machines from the existing fleet which were retrofitted.

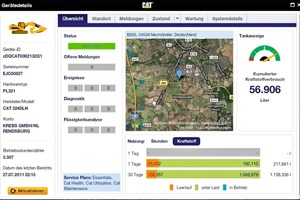

The fleet management is used for control of the machines – the Ernst Krebs fleet consists of around 70 machines, including wheel loaders, mini-, mobile, and chain excavators in a wide range of size classes. Pending maintenance work, for example, is read and evaluated by the master mechanic Jan-Oliver Duske, who with one colleague responsible for repairs to trucks and construction machines in the company’s own repair shop looks at the values. VisionLink provides a clearly arranged user interface displaying all key data of the machine fleet. To undertake and initiate servicing at the right time, the current service interval is displayed with the traffic light colours red, amber and green. In addition, the average working hours of the last week are documented in order to enable appropriate evaluation (Fig. 2).