“Made-to-measure” dredger

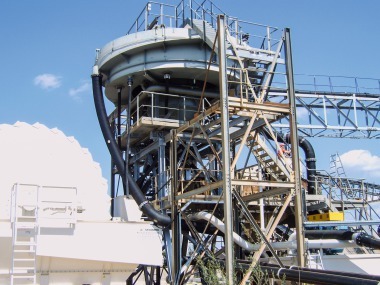

In Oberhergheim, in the Alsace region of France, Gravière des Elben, a subsidiary of Reinhard Waibel, a gravel works and shipping company headquartered in Gernsheim, operates a B400 floating grab dredger supplied by BEYER in Viernheim, Germany. Working from the geological situation at the extraction site, BEYER cooperated closely with the operator to select the most suitable extraction technology for this problematic deposit and designed an extraction machine “made to measure” to cope with conditions there.

An important feature of the extraction areas at Oberherg-heim are naturally solid aggregates, about the size of boulders, which are made up of sand and gravel bonded with silicates. The average dredging rate was designed at 300 t/h at 70 m dredging depth. As the shape of the agglomerates sometimes means that they can only be held with just one pair of grab teeth, resulting in an extreme one-sided load on the grab jaws, the company opted for the proven rope grab system. Unlike the hydraulic grab, which applies its closing force depending on the dynamics of the hydraulic unit, the rope grab has a “softer” action and can be manipulated at any time thanks to the frequency converter technology, therefore protecting the structure. To ensure the necessary grab performance, an extra heavy grab was chosen, so that a 40-tonne winch was needed for the 10‑m3 grab.

So that the extracted sand and gravel can be continuously transported on floating and overland belts to the installed processing plant, downstream of the grab is a hopper with oscillating lock feed to a screen (Fig.). The undersize of the dewatering deck is channelled to a vertical pump and recovered with the help of a cyclone.

The company opted against sand processing initially. Preparations for intensive spraying of the dewatering screen and for a separate sand dewatering machine have, however, already been made. The dewatering screen has recesses in the sidewall which are currently closed up but can be opened up at any time for the spray nozzles. In terms of space and weight, the pontoon is also design to accommodate later changes and retrofits. Life is breathed into the mechanical systems by the Siemens electronic engineering used at BEYER. Programs specially developed by BEYER, which can draw on a 40-year development and optimization process, ensure quiet and trouble-free operation.

As BEYER has installed the electrical cables in pipes on the pontoon, the clearly structured and easy-to-follow arrangement on the dredger is particularly striking. On the dredger there is no confusion of connections, holders and cable ladders on which rocks and dirt can settle. All in all, the intensive cooperation between the gravel works operator and dredger builder led to an extraction machine optimally adapted to the site conditions. Equal account was taken of the geological, technological and economic aspects.