Minimizing build-ups and chute plugging

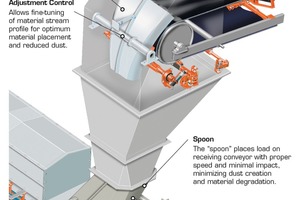

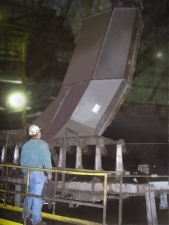

By managing the material speed and direction, the new MARTIN® Inertial FlowTM transfer chutes (Fig.) can minimize impact and wear on liners and belts, while containing the dust and spillage that are often generated at transfer points. The engineered flow chutes employ special geometries that capture and concentrate the material stream as it travels through the chute. Every design is tailored to suit the specific material characteristics and conveyor systems of the individual customer. Inertial Flow Transfer Chutes from Martin Engineering provide the dual benefits of minimizing aeration and preventing buildup within the chute, particularly important when dealing with combustible materials.

MARTIN ENGINEERING GmbH, Walluf (D),

Tel.: +49 6123 9782-0, www.martin-eng.com