New developments in conveyor belt cleaning systems

REMA TIP TOP specializes in studying customer requirements and passing on the results of these studies to its own product development department, while supporting conveyor operators with advice and action in order to supply the belt cleaning systems that are most suitable for meeting operator needs.

Belt conveyor uptime is often related to the effectiveness of belt cleaning. Material losses and caking of material onto the conveyor and the resulting faults must be minimized. There is no single universal belt cleaning system that can handle all applications in a particular industry. The cleaning effect depends on many factors, both the design parameters of the system and the material conveyed. Here product properties such as moisture content, stickiness, chemical composition, particle size as well as external factors, such as the ambient temperature, play an important role.

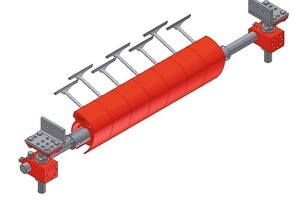

The latest REMA TIP TOP belt cleaning developments REMACLEAN HM-U7 and HM-U8 (Fig.) represent a new generation of patented belt cleaning scrapers. These are precision cleaners fitted with hard metal scrapers and highly effective kinematics. The hard metal scrapers can move in two dimensions and are self-adjusting to fit the conveyor belt surface. The scrapers overlap, thus guaranteeing 100 % cleaning. The hard metal scrapers are mounted in polyurethane feet. Sleeve bearings and shaft seals ensure correct functioning. The polyurethane feet have a special function: they store the pre-tensioning force of the cleaner, and ensure that the hard metal scrapers always have the optimum contact pressure. This permits gentle cleaning by the scrapers and, at the same time, high cleaning performance. The scrapers are equipped with extremely wear-resistant hard metal inserts. Moreover, the polyurethane segments can be individually fitted to and removed from the carrier without the need for special tools. Fast exchange of replacement parts and short fitting times pay off through operational costs. The REMACLEAN HM-U7 and HM-U8 can be used for many conveyor belts and are currently available for belt widths of 500 to 1800 mm. A variant that conforms to ATEX for use in opencast mining is also available.

REMA TIP TOP GmbH, Poing (D), Tel.: +49 8121 707 245, www.rema-tiptop.de