Track-mobile machines in action in the Polar border region

For the first time, the Mineral Processing Technology business unit of the German company HAVER & BOECKER based in Münster has developed and engineered a heavy-duty HAVER NIAGARA T-Class® 2-bearing screening machine and a weighty HAVER NIAGARA® UF® vibrating feeder for track-mounted operation in the Polar border region. The two machine types have been specially adapted to the requirements of Haahjem AS, the Norwegian manufacturer of mobile plants based in Vigra and renowned for its heavy-duty CTC mobile plants with a total weight of over 100 t.

The focus here was on the adaptability of the machine to achieve the desired performance as well as high levels of flexibility. In addition, paramount importance was given to the machines’ availability and functionality in a harsh environment with extreme weather conditions as part of a Haahjem CTC 136 S3M track-mobile secondary crushing and sizing plant with a feed rate of up to 500 t//h. The unbalance parameters can be quickly adjusted over a broad range. Accordingly, the HAVER NIAGARA T-Class® 2-bearing screening machine has been equipped with a pre-heatable circulation oil lubrication, which ensures a safe machine start-up and a long service life of the bearing for these low ambient temperatures.

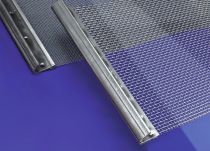

The drive of the HAVER NIAGARA UF® vibrating feeder consists of robustly built unbalance motors. In the meantime, two Haahjem CTC 136 S3M track-mounted secondary crushing and sizing plants equipped with a HAVER NIAGARA UF® vibrating feeder 1200 x 4500 and a HAVER NIAGARA T-Class® 2-bearing screening machine S150 1800 x 6000 – 3D have been sold. One mobile plant is currently being shipped to its operating site in Russian Karelia, whereas the second plant is ready for transport to the polar border region, to Jamal in Siberia. The managing partner of Haahjem AS, Kristian Haahjem, is enormously satisfied with the highly sophisticated machines supplied by Haver & Boecker. Trial runs with material on the site of Haahjem AS in Vigra, Norway, have confirmed this (Fig.).

HAVER & BOECKER Maschinenfabrik Münster, Münster (D), Tel.: +49 251 9793-0, www.haverboecker.com