New model

Analysis and simulation of hydrocyclone performance

with an advanced model of the Tromp curve

Summary: The quality of products milled in closed circuit grinding can be influenced significantly by controlling the density regime of hydrocyclones. In a recent research work done by the

author conducted at a pilot plant at Cemtec GmbH/Austria, this influence was investigated.

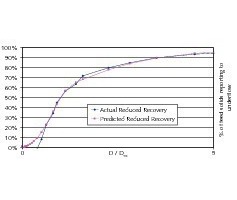

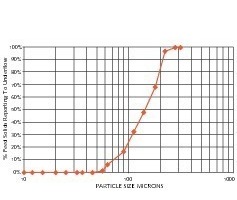

The best way of analyzing product qualities and the overall quality of separation is the recovery curve. With varying water splits the upper and lower tails of the curve do vary quite significantly. For analysis this is not a problem, however for predicting cyclone performance a new approach to recovery curve simulation and shaping is needed because traditional models only suggest a symmetrically shaped curve. This paper describes the various types of recovery curves, how they are calculated and shows a way of moving from symmetrically shaped recovery curves to a more detailed approach, where the lower part of the recovery curve can be shaped individually, so that the prediction can be fitted to different water splits.

1 Introduction

Growing demands for product quality in the minerals industry are of greater importance than ever and a growing challenge for all producers. The first step in mineral processing is usually comminution. In this process step, the correct particle size distribution for all downstream processing is produced and at the same time the foundation for final efficiency and product quality is laid. The quality of this milled product can be significantly influenced by controlling the density regime of a hydrocyclone in closed circuit grinding. In a recent research work done by the author...

![Recovery curve of a hydrocyclone [15]](https://www.at-minerals.com/imgs/tok_0c7b0e431a2c5810c0720a33f68dca69/w237_h200_x118_y141_101294578_0c994e0107.jpg)

![Actual and corrected recovery curve of a hydrocyclone [1]](https://www.at-minerals.com/imgs/tok_6a43d07447518fab758e2e4ceade4a51/w237_h200_x118_y184_101294590_e98264db4c.jpg)

![Reduced recovery curve of a hydrocyclone [1]](https://www.at-minerals.com/imgs/tok_7db60498118854431d594f692d9cf209/w237_h200_x118_y170_101294589_d7fda95d83.jpg)