Energy saving

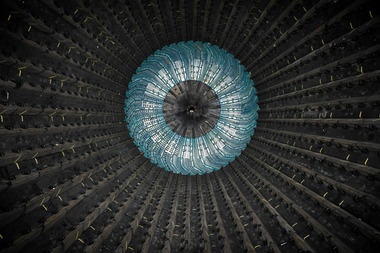

Development and testing of a ceramic classifying lining

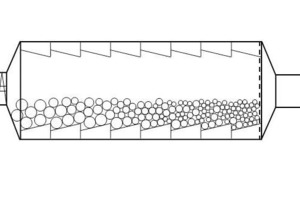

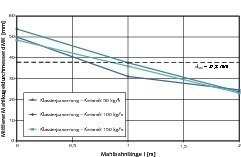

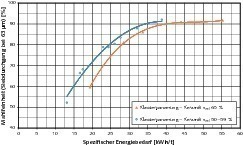

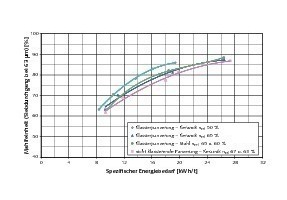

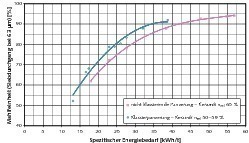

Summary: For grinding high-grade speciality products with strict specifications for particle size distribution, purity and reactivity, tumbling mills with non-classifying linings and grinding media made of special ceramic are used. To improve grinding efficiency, a ceramic classifying lining was to be developed and tested. In semi-industrial grinding tests with silica sand and limestone, it could be proven that energy savings or increases in throughput rates between 5 -25 % can be achieved with the new lining.

1 Introduction

Grinding processes are of considerable economic significance. Take, for example, the production of binder building materials, ore beneficiation, the processing of industrial minerals or coal, chemical products, and the production of metal powders, etc. For the grinding of the above-mentioned materials, mainly tumbling mills are used. In their over hundred years of development, these have been improved so far in respect of their design and technology that today they are reliable, effective and easy-to-use machines, but with regard to the milling of bulk solids, no further...