EIRICH strengthens its second business unit grinding technology

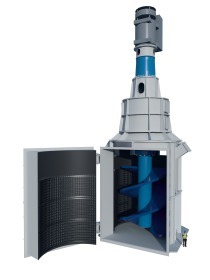

A key process step for many industries when preparing raw materials is fine and very fine grinding. Up to now EIRICH has offered agitated media mills for this task. Now it has added three more models to its range of mills, along with classifying technology. The company (Fig.) will be presenting its expanded range of grinding technology to professional circles for the first time at the forthcoming POWTECH.

Up to now EIRICH, as a specialist in processes and techniques for the preparation of powder and bulk solids, has focused on agitated media mills when it comes to grinding technology. The MaxxMill® served the core market of the ceramic industry and industrial minerals, while the TowerMill covered the core market of the processing of ores. Through acquisition in the market, the product range has now been extended by other types of mills and air classifiers:

● Centrifugal ball mill with vertical axis, for the dry grinding of soft to medium-hard materials. Grinding and simultaneous drying of wet, plastic materials is possible

● Attritor mill for the dry grinding and disagglomeration of soft, low-abrasive materi-als. Suitable for the simultaneous grinding and drying of moist, plastic material

● Ball mill with horizontal axis for the dry grinding of abrasive and hard materials. Improvements in terms of design and construction facilitate the optimum transport of the material in very fine grinding processes

● Dynamic air classifier for particle top cuts of 5 to 400 μm for fine materials. For sharp classification in the very fine range, a patented multi-wheel air classifier is offered

The mills are available in a range of sizes and with different linings as well as for iron-free grinding. With the expansion of its range of mills EIRICH is now in a position to offer customers in the international markets grinding concepts for a wider range of applications and the best solution for each specific task.

Hall A4, Stand 409

$(LEhttp://