Attack on wear and corrosion

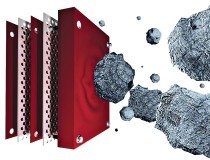

Effective wear-protection solutions made of ceramic such as basalt, alumina or zirconia for foundries, the minerals, cement, coal or chemical industries have so far almost always meant a not inconsiderable increase in the weight of the pipes, lines or bends. Now the company Th. Scholten GmbH & Co. has not only developed a process that contributes to a considerable reduction in weight, but also provides almost 100‑% corrosion protection (Fig.): instead of the steel shell, infinitely long glass fibres (roving) are wound around the inside wear-protection material and then wetted with resin.

GRP has been used for decades in equipment exposed to a risk of corrosion; new is now its use for wear protection. This system boasts several advantages: nominal width conformity is possible and a high chemical resistance is guaranteed. In addition, GRP is an economic alternative to other material combinations with rubberized steel and ceramic. New is also the possibility of endless laying of the pipes without flanges. A socket/laminating system is used to endlessly join pipeline sections. Another benefit is the simple and also partial repair. Worn pipe sections can be directly cut-out of the pipeline and replaced with new wear-protected pipe sections. Scholten supplies GRP pipe sections with monolithic ceramic cylinders from DNi 25 to DNi 700 mm rated diameters. Larger diameters are manufactured individually with custom-fit ceramic wedges.