Wear protection in conveyor systems

Steel is considered the material of choice for protecting surfaces against wear in conveyor systems for heavy materials. In practice, however, steel reaches its limits in many cases. Rico Harting, Product Manager at REMA TIP TOP, has been developing solutions for efficient and sustainable wear protection in conveyor systems for many years. In this interview, he explains which alternative materials should be considered for wear protection and how modern composite systems such as REMALOX HD help to reduce repair and maintenance costs and significantly increase operating runtimes.

What are the key challenges in conveying heavy materials?

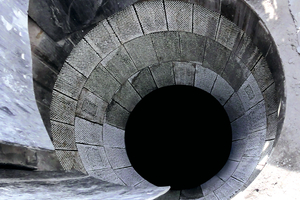

Rico Harting: It is no secret that heavy or sharp-edged conveyed materials such as stones and ores are more abrasive than light or round materials. Therefore, increased wear can occur along the entire production process. Loading and transfer points, where the heavy material is transferred from a conveyor belt into a hopper or onto a chute, for example, are particularly critical. Depending on the conveying speed, drop height and impact angle, wear on component surfaces can be particularly high here. This increases maintenance and servicing costs and reduces the service life of a system. Some companies have to stop the operation of their conveyor system several times a year to maintain the wear protection at critical points.

What role does steel play in protecting against wear in conveyor technology today?

Rico Harting: Steel is undoubtedly considered the material of choice for protecting the surfaces of vibratory conveyors, cyclones, chutes, loading points, hoppers, etc. against wear caused by heavy materials being conveyed. Plates, sheets and strips are usually used, with wear-resistant steel alloys depending on the load. In medium to heavy-duty applications in mining and quarrying, and also in gold mines, steel is very common for lining surfaces, although steel is not always the best solution in individual cases. Operators often rely on steel despite the fact that lighter solutions made of rubber would be more suitable. Others stick to steel despite the fact that it does not meet the demanding requirements.

Where does steel reach its limits in wear protection?

Rico Harting: Although steel plays an important role in wear protection in the conveying of heavy materials, there are application scenarios where steel reaches its limits and other wear protection technologies lead to better results. When conveying highly abrasive materials, even highly wear-resistant steel can become severely worn over time. Edges are ripped or fatigue cracks occur due to shock impact. In addition, steel can corrode under extreme conditions – such as moisture, heat and acid. And anyone who has experienced iron ore dropping from a great height into a hopper with a steel lining can confirm that steel does not help to protect against noise in plants. Other materials or composite systems are often more suitable in these cases.

What are the alternatives to wear protection with steel?

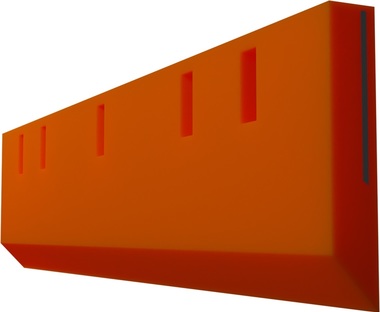

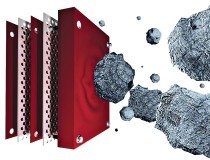

Rico Harting: As alternatives to steel, rubber, ceramics and composite systems made of these two materials are generally considered for wear protection in conveyor systems. One advantage of rubber is that it can elastically compensate for the impact of conveyed material, which significantly reduces noise in the system, among other things. However, rubber is only suitable for heavy materials to a limited extent. A better alternative in this case is wear protection made of ceramic plates and components, which are very resistant. That said, ceramics are relatively brittle, which is not a problem when heavy material slides or rolls over the surface. It becomes critical, however, when the material being conveyed impacts vertically on the ceramic surface from a great height. In such cases, surfaces can break and edges can flake off.

What advice do you have for companies that want to improve their wear protection?

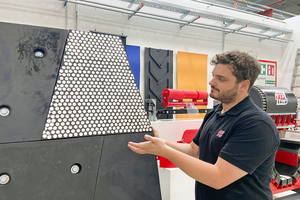

Rico Harting: It is worth looking beyond steel, rubber and ceramics and taking a look at new concepts. Composite systems such as REMALOX HD combine the strengths of rubber and ceramics to provide durable and economical wear protection. REMALOX HD features a rubber matrix that absorbs impact energy, while embedded ceramic elements protect against wear. A metal backing enables easy screw fastening to the application surfaces. REMALOX HD has proven particularly effective in plants with large conveying volumes of crushed material, long maintenance intervals of 12 to 15 months, and structurally unfavorable impact angles, where ceramics alone are not suitable for robust wear protection.