Allgaier Process Technology GmbH

During the extraction of limestone in quarries, so-called pre-screening debris are generated. Up to 90 % of this pre-screened material consists of good limestone rock, which is frequently heavily interstratified with clay and loam impurities. Therefore, it could only be sold as a low-grade product without being correspondingly cleaned.

Usually wet washing processes are used, so-called rock washing plants known from sand and gravel processing, to remove the pollutants adhering to the limestone. Then the washed materials have to be dried before further processing (crushing, screening, classifying, burning). The use of rock washing plants requires an expensive sewage and sludge treatment and, only for this reason, cannot be used without problems everywhere. The required capital spending and power for such plants, in particular combined with drying, are considerable, also because the washing of the rock leads to the a higher water content exceeding the original rock moisture. It would not be reasonable to operate rock washing plants in regions with heavy frost or arid areas, from the technical and economic point of view.

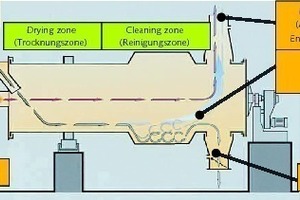

The delivery program of Allgaier includes a special rotary dryer, which makes the use of rock washing plants unnecessary. The patented drying and cleaning drum system MOZER® TRH combines the process steps of drying and cleaning in one unit. After a quick pre-drying of the rock in the first part of the dryer, the loam and clay components adhering to the limestone are separated by means of a carefully controlled combination of retention time and mechanical stress in the second part of the dryer with an extended diameter drum. Fine components of the separated pollutants are discharged to the filter plant already with the waste air of the dryer, while the remaining pollutants, which, however, are separated from the rock, can be separated from the cleaned limestone rock by means of screening plants.

By a technical-commercial study the combined Allgaier drying and cleaning drum, type TRH, and traditionally rock washing plants with downstream dryers has been compared. For this purpose, comprehensive measurements of the cleaning quality as well as of the consumption of energy and inputs were carried out on various existing, large-scale plants of both systems, and the staff required, repair and maintenance costs as well as the investment required of both solutions were determined and compared.

The Allgaier drying and cleaning drum is distinguished by very good cleaning results, a particularly efficient operating mode as well as moderate and relatively low investment and operating costs. The results of the system comparisons carried out are to provide well-founded fundamentals for decisions of potential plant operators as regards a possible investment. Allgaier is able to offer large-scale tests with real materials in existing industrial plants.

Hall B2; Stand 219