BEUMER Group provides engineering of stockpiles for the coal industry

BEUMER Group offers a comprehensive product and system solutions portfolio to customers from the coal mining industry. Conveying technology includes closed Pipe Conveyors and open troughed belt conveyors that can be adjusted to the respective situation. As a system supplier, BEUMER Group also provides extensive know-how and the necessary components for storing hard coal, e.g. stackers and bridge reclaimers. “We support our customers immediately from the design phase,” says Andrea Prevedello, System Technology Global Sales Director, BEUMER Group, Germany. Drone technology is used more and more frequently during project planning, implementation and documentation to optimise the design phase. The recorded aerial photos are rectified with regard to their perspective and evaluated photogrammetrically. The software calculates a point cloud in order to generate 3D models from the two-dimensional views, i.e. digital terrain models. Stockpiles can now be greenfield and brownfield developments.

“We have some major customers with very interesting projects in this sector,” explains Andrea Prevedello. This most certainly includes Prairie Eagle Mine in Illinois, the largest coal mine of Knight Hawk Coal. This is one of the most efficient underground mining plants in the US. They produce approximately 5 million tons of coal annually, of which more than 80 % is processed and delivered in Prairie Eagle.

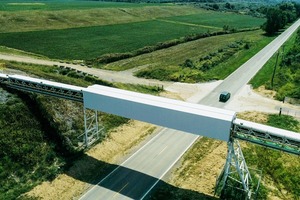

Management was looking for a more sustainable operating solution. “We provided an overland conveyor that transports the coal from the mine to the main processing plant,” describes Andrea Prevedello. “Our conveyor helps the company to considerably reduce its ecological footprint. With this technology, Knight Hawk can significantly reduce its long-term environmental impact compared to using truck transportation.” BEUMER Group not only supplied the conveying solution. As a system supplier, the company also supported the mining group in building a stockpile for hard coal. “The requirements for storing coal are obviously very different from other materials,” explains Andrea Prevedello. Some of the important requirements are changing if the stockpile is covered and if explosion-proof specific equipment is needed. Hard coal is very susceptible to spontaneous combustion, which is why the height of the stockpile must be in certain cases limited.

Circular or longitudinal stockpile?

Depending on the customer, stockpile dimensions and design can vary. Two layouts are generally available: circular and longitudinal. “Their dimensioning and design depend on the purpose of the stockpile,” describes Andrea Prevedello. Space availability and possible future expansions are also critical factors. The application must also be considered: does the customer want to store the bulk material temporarily, then continuously feed it for further processing, like Knight Hawk? “Then longitudinal stockpiles are your best choice,” says Andrea Prevedello. They can also be extended, if necessary. The irregular flow of bulk material arrives at the stockpile and can then be continuously introduced to the process. Circular stockpiles are frequently used for other bulk materials as well, e.g. for limestone, clay. This is particularly used by cement manufacturers and power plant operators.

But back to coal. Once the layout of the stockpile has been decided on, the next task is to stack the bulk material efficiently. BEUMER Group also provided these necessary components such as the stacker. “Depending on its mobility, the systems can be categorised into three groups,” explains Andrea Prevedello. The stacker can be stationary, travel on rails or be circular with endless movement. If the machine is circular with endless movement, it is positioned on a column in the centre of the stockpile. Over a conveyor bridge installed above the stockpile, the material is transported directly into the axis of rotation of the stacker and from there distributed centrally. Depending on the stacking method, the boom conveyor can be fixed or it can be lifted and tilted.

It depends on the method

The stacking method of choice depends on whether the bulk material is only temporarily stored or if it also needs to be blended. “For simple stockpiling without blending, we provided with the simple ’cone shell method’,” describes Andrea Prevedello. The stacker only moves up and down, not slew. The stacker design can be more simpler. This method works for longitudinal as well as circular stockpiles. For blending the bulk material however, the Chevron method can be used. The boom of the stacker starts in its lowest position. The first row is deposited in the centre of the stockpile, the next rows are layered on it. In longitudinal stockpiles, the stacker usually moves in a tilting and slewing motion, in circular stockpiles the stacker moves in a circulating and luffing motion.

Efficient coal mining

“The perfect system solution is always an optimal relation between stacker and reclaimer,” explains Andrea Prevedello. Reclaimers such as side reclaimers or bucket wheel remove the material, as necessary. The best option for the customer depends again on the stockpiling task at end. Side reclaimers work for both types of stockpiles, longitudinal or circular. The bulk material can be reclaimed from the front or the side. When reclaiming from the side, scraper chains move the material on a belt conveyor. Front reclaiming usually uses a rake that in small side-to-side movements pushes the material on a scraper chain to be transported further to the conveyor. The advantage is that the bulk material is reclaimed from the entire cross-sectional area. Bucket wheel are used in particular when the bulk material, especially in large quantities, needs to be blended.

Each operator has their own very specific requirements on the stockpile and stockyard machines. This is shown in a project that the BEUMER engineers are currently implementing for a customer in the energy industry. The order includes the delivery of several conveyors, including Pipe Conveyors, and a ship loader. The challenge: “On the ground where we will install our solution, there can be violent gusts of wind,” reports Andrea Prevedello. “That’s why we pay special attention to the dimensioning of the steel structure.” The system provider will thus be able to hand over a tailor-made system to the customer, with investment expenditure tailored precisely to him. The expected commissioning is scheduled for the third quarter of 2020.