Owl Eye® – Inventory monitoring of bulk material stockpiles and stockpile management

1 The Owl Eye Monitoring System enables accurate stocktaking in storage boxes

1 The Owl Eye Monitoring System enables accurate stocktaking in storage boxes

© Sachtleben Technology

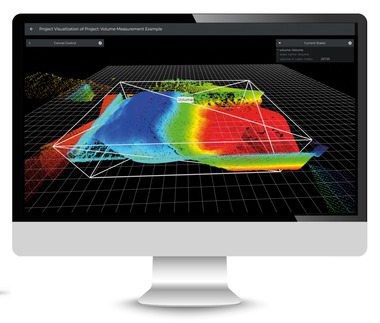

The system has an integrated database application, an intuitive dashboard and interfaces with the process control system. It also offers valuable analysis functions for more efficient stockpiling. Through the permanent monitoring of the bulk stockpiles, companies can get an overview of their stocks at any time and detect any deviations at an early stage. The Owl Eye Monitoring System is also able to process and manage data from external systems. This enables even more comprehensive monitoring of the bulk material stockpiles and even more efficient use of the data.

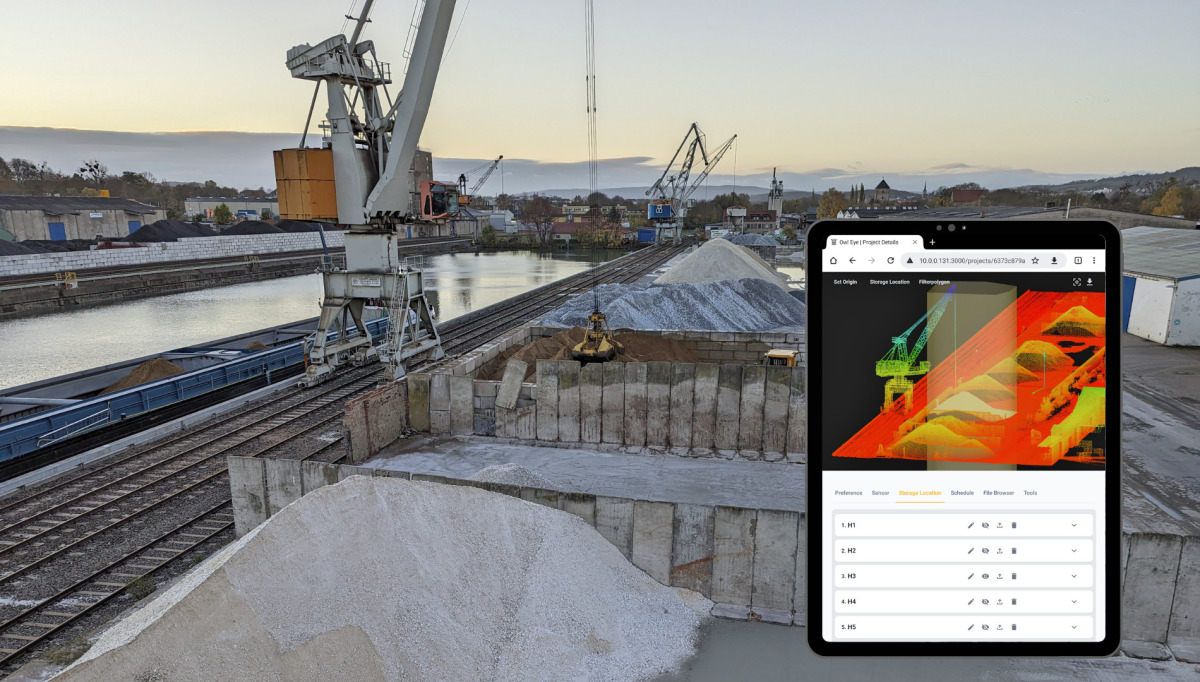

2 Digital inventory monitoring of bulk stockpiles is also possible in port facilities

2 Digital inventory monitoring of bulk stockpiles is also possible in port facilities

© Sachtleben Technology

In addition to the Owl Eye Monitoring System, Sachtleben Technology GmbH offers a bulk material inventory as a service. This involves scanning any bulk material stockpiles, regardless of their form, for example for an end-of-year inventory. Companies can thus obtain a precise overview of their bulk material stockpiles and optimise their warehousing.

Sachtleben Technology GmbH stands for innovative solutions and, especially with the Owl Eye Monitoring System, offers companies a simple and efficient way to monitor their stocks and optimise processes.

Hall 4, stand A 11